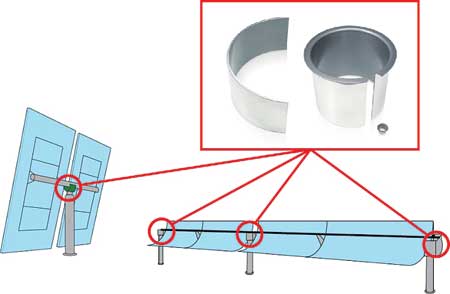

CSP parabolic troughs reflect sunlight onto a central tube, heating the fluid within to make steam for electricity generation.

Composite bearings used in CSP solar tracking systems ensure smooth movement with minimum maintenance.

An early glimpse into the 2013 Annual Energy Outlook from the U.S. Energy Information Administration reveals that increased generation from renewable energy is expected to account for 32 percent of the overall domestic growth in electricity generation from 2011 to 2040. With this insight and reports of global growth forecasts in renewable energy from both financial and market analysts in mind, Saint-Gobain Performance Plastics announced its strategic initiatives for composite bearings applications in renewable energy markets.

"The Bearings and Tolerance Rings Group at Saint-Gobain designs composite bearings solutions that withstand harsh vibration, improve efficiency, extend performance and reduce operational downtime in both solar energy and wind turbine applications. As part of its strategic focus in renewable energy markets, Saint-Gobain has added the design engineering expertise of Industrial Global Market Manager, Edward Rumble to its team. With his extensive design and engineering experience, Rumble will lead the increasing efforts to develop the next generation of composite bearings for solar and wind applications," said a company spokesperson.

"Renewable energy, fueled by innovative solar and wind turbine technologies, will prove to be the future of sustainable power generation," said Rumble. "To help today's and tomorrow's leaders in renewable energy production, we are committed to partnering with OEMs to deliver innovative solutions that enhance efficiency in solar and wind applications."

"For the solar market, Saint-Gobain manufactures an innovative, maintenance-free composite bearing. Proprietary fluoropolymer compounds in SOLGLIDE composite bearings increase the long-term operational efficiency of solar equipment, reduce energy usage and decrease long-term costs. SOLGLIDE composite bearings are specifically designed for Concentrated Solar Power (CSP) plants, applied at pivot points in all major tracking systems," said the spokesperson.

For the wind turbine market, in 2013 Saint-Gobain will introduce a series of composite bearings solutions. "Our application engineering teams are currently developing the next generation of composite bearings technology for wind turbine applications," said Rumble. "The composite bearings will be able to withstand the harsh vibrations that occur in wind turbine applications while reducing operational downtime. This is the next step for Saint-Gobain in offering solutions that enhance the production of renewable energy."

Efforts within the operation of Saint-Gobain are also making significant strides in sustainability. The Environmental Protection Agency (EPA) recently recognized Saint-Gobain with the 2013 ENERGY STAR Sustained Excellence Award for Continued Leadership in Energy Conservation for the third consecutive year. Over the last year, the company achieved energy savings of three percent, equating to avoiding more than 82 tons of carbon dioxide emissions.

For more information contact:

Saint-Gobain Performance Plastics Corporation

150 Dey Rd

Wayne, NJ 07470

973-696-4700

www.plastics.saint-gobain.com

www.bearings.saint-gobain.com