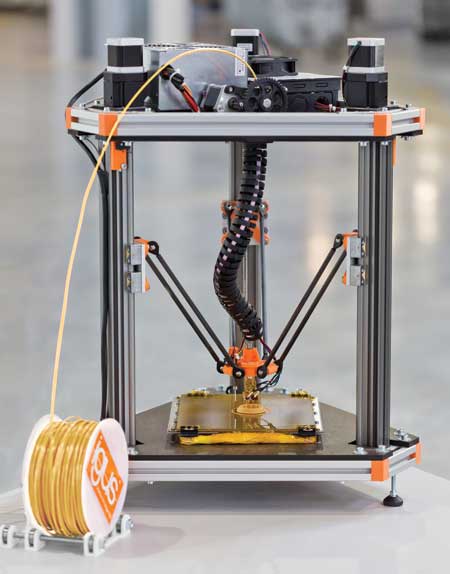

Printable Bearing Material Filament for 3D Printers

March 1, 2015

"igus' tribo-optimized filament for 3D printers is up to 50 times more abrasion-resistant than conventional 3D printer materials," said a company spokesperson.

igus has introduced a plastic filament for 3D printers enhanced with tribological, or low friction, properties. "The material, 50 times more resistant to wear and abrasion than conventional 3D printer materials, is ideally suited for creating custom bearings," said a company spokesperson.

"This is the first filament for 3D printers specifically developed for motion control applications," continued the spokesperson. "Currently, igus carries 45 different high performance plastics as optional materials available for iglide products, with a further 100 custom materials suited to specific customer needs. Moving forward, the new filament will give customers more flexibility for the design of their application's bearings. Even prototypes can be produced quickly and cost-effectively."

igus also offers access to 3D models of igus products in STL format, which can easily be downloaded and used directly as input data for 3D printing.

For more information contact:

igus, Inc.

P.O. Box 14349

East Providence, RI 02914

800-521-2747 / 401-438-2200

sales@igus.com

www.igus.com/3dfilament

< back