Arcor Laser's precision laser tube cutting system, engineered for fully automated cutting of tube material, is designed to provide the high precision and repeatability required for special shapes in the medical industry.

"Laser cutting is fast, flexible and cost effective, while providing a considerably better finished result than other processes," said a company spokesperson.

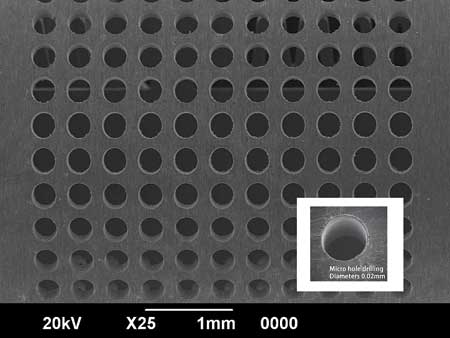

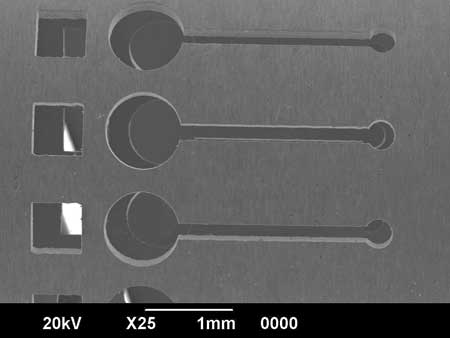

Arcor's laser drilling process is designed to be an inexpensive alternative to mechanical drilling and is very adaptable for small holes with large depth-to-diameter ratios. "Laser drilling provides a repeatable, accurate hole that can be customized for all types of manufacturing industries," said a company spokesperson.

To create holes with laser drilling, one of two processes is used. Percussion drilling is performed by repeatedly pulsing the focused laser energy at a material surface, vaporizing layer by layer. For cylindrical parts such as aerospace combustor liners, a separate process called drilling on the fly (DOF) is used in which percussion holes are drilled while the part is in motion.

According to the company, precision laser drilling and shaping is suitable for the following applications:

- Cutting thin glass

- Cutting computer chips

- Cutting narrow slots

- Drilling holes down to 15 um

- Ablating a variety of shapes

- Hole drilling in a variety of materials such as titanium, nickel, aluminum and stainless steel alloys.

"Lasers can cut most metals, including steel, stainless steel, super alloys, copper, aluminum and brass, as well as many non-metallic materials such as ceramic, quartz, plastic, wood and certain composites down to .001 kerf," said the spokesperson. "Laser drilling provides consistency for industries having manufacturing specifications that require tight tolerance for high depth-to-diameter ratios. The process can provide dynamic changes of hole diameter and depth and edge quality. Shaped holes of almost unlimited geometry are now possible producing unique benefits previously unobtainable by conventional processing techniques.

"Our team of laser engineers can produce complete parts, from prototypes to large production runs. We offer contract manufacturing services from original concept through tool design and fabrication, from laser welding, drilling, cutting and marking to fully integrated turn-key systems."

For more information contact:

Arcor Laser Services, LLC

4 Kenny Roberts Memorial Dr.

Suffield, CT 06078

844-770-8980 / 860-370-9780

www.arcorlaser.com