LASERTEC 45 Shape - economical and reliable with no tool wear

LASERTEC 65 3D

LASERTEC 65 3D - Laser deposition welding and milling in a single setup

Complex part for the die & mold industry.

The LASERTEC 65 3D and the LASERTEC 4300 3D are able to deposit multiple alloys in a single build.

The DMG MORI LASERTEC portfolio includes five technology segments: The PrecisionTool is suited for the machining of cutting edges and clearance angles in diamond precision cutting tools. With its FineCutting solution DMG MORI enables high-precision laser fine cutting of sheet metal, tubes and 3-D parts. The segment PowerDrill stands for the dynamic 5-axis laser drilling of cooling air holes in turbine components. The LASERTEC 45 Shape and the LASERTEC 65 3D in the segments Shape or Additive Manufacturing are among the latest developments being presented by DMG MORI. The latter technology is a combination of laser deposition welding and 5-axis milling for the additive manufacturing of complete 3-D components in finished part quality. The Shape technology uses 3-D laser ablation for small integrate parts or to achieve defined textures in injection molding tools.

LASERTEC 45 Shape

DMG MORI's Shape technology is a productive way of machining intricate structures and injection molding tools. "Machining is carried out directly on the workpiece, so there is no longer any need for the separate machining of electrodes," said Friedemann Lell, Head of Sales for the LASERTEC machines. "This reduces production times, especially where fine, detailed parts are concerned. The fact that there is no wear on the tools also contributes to process reliability and cost effectiveness. And all this for a batch size of one, because there are no tool costs and CAD data can be imported directly."

Another application for Shape technology is the structuring of injection molding tools. This allows the texturing of irregular shapes (e.g. leather texturing) or geometric structures (e.g. pyramid structures). Creating geometric structures takes immense time and effort without a laser or in some cases cannot be achieved at all.

In every specific application, the respective CAD data defines the geometric textures to be applied on the component. Actual laser ablation is carried out in horizontal layers with thicknesses between 0.3 and 10 µm depending on the laser and material. This allows the creation of 3-D structures on the workpiece. "Even small tools can be produced directly with this technology," said Lell. "It is also suitable for miniature molds, stamping tools or the lettering and engraving of coins and medals."

The new LASERTEC 45 Shape work area is 80 percent larger than the LASERTEC 40 Shape on the same size footprint. Travel and load capacity have also been increased. There is now also a 5-axis version, which has space for components of up to o 12" x 8" and weights of 220 lb. The A-axis has a swivel range of -100° to +120°. The machine technology includes the interaction of precision optics - consisting of a laser head with the latest scanner optics technology and a CCD camera - and the dynamic deflection mirrors. Rapid traverses of 60 m/min are more than three times faster than those of the predecessor machine.

LASERTEC 65 3D

With its LASERTEC 65 3D, SAUER has made a step forward in the additive manufacturing segment. The LASERTEC 65 3D provides the combination of laser deposition and milling in a single set-up. "This enables the production of highly complex components like those with 3-D geometries with undercuts or, for instance, conformal cooling of injection molding tooling," said Lell. These cooling passages are made by laser deposition. In many cases this can allow the currently installed base of injection molding equipment to be operated at higher throughput by reducing the required cooling time for each "shot."

"The process of laser deposition and milling in a single set-up proves invaluable especially where the production of prototypes are concerned or in the small series production of complex lightweight and integral components. We envision applications in tool and mold construction, in aerospace, automotive as well as medical technologies," said Lell.

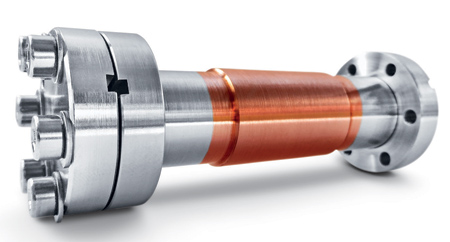

The LASERTEC 65 3D utilizes a powder nozzle to apply the metal powder - stainless steel or also many different alloys such as tool steel or nickel-based alloys - in layers onto the base material with which it then fuses in the melting point of the laser beam. This is a high-strength pore and crack-free fusion bond. An inert gas prevents oxidation during the build-up process. After cooling, a layer of metal forms, which can then be machined mechanically. This process also allows bimetallic depositions that can include copper cores to dissipate heat or hard-facing to resist wear.

With the combination of laser deposition and milling on a single machine this process can now be carried out in one set-up. "As both machining processes can be used alternately, many 3-D contours can be produced completely without the need of any supporting geometry," said Lell. "Laser deposition welding is ten times faster than the conventional powder bed method. For final milling the component does not have to be re-clamped somewhere else."

DMG MORI unites the technology of the monoBLOCK concept from the machining center sector in the LASERTEC 65 3D. "For laser deposition welding we use a completely new laser head with integrated cooling, process monitoring and an integrated camera that controls the process optically and adjusts the laser power online," said Lell.

LASERTEC 4300 3D

DMG MORI added the LASERTEC 4300 3D to its portfolio last year. The machine supports larger work envelopes and offers 6-axis deposition as well as the capability to automatically change between various deposition heads. This allows miniature deposition heads to traverse complex cavities for repair, or large deposition heads to lay down ribbons of metal, up to 22 lb. per hour. "The machine has the ability to deposit multiple alloys in a single build, typically copper and nickel based alloys for nozzles, thrust chambers and ignitors for rocket motors," said Dr. Greg Hyatt, Vice President & CTO, DMG MORI Advanced Solutions. "Support for deposition of titanium drove the second wave of acceptance, this time in aerospace structural applications. And now the ability to deposit dual alloys including abrasion resistant tungsten carbide or cobalt-chrome has found drilling applications in the energy market."

For more information contact:

DMG MORI - Americas Headquarters

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

Service Hotline: 855-DMG-MORI (364-6674)

www.us.dmgmori.com