The handle in the deep bin

No caption provided

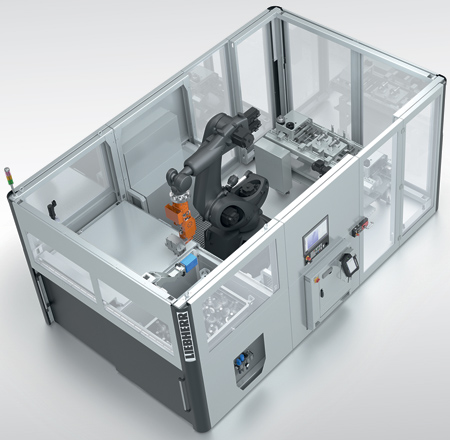

The smart removal of workpieces from a random arrangement, called bin picking, is a classic automation application. It provides higher productivity, less burden on human resources and lower unit labor costs.

Liebherr-Verzahntechnik GmbH, acting as a turnkey provider, has developed key robot cell solutions for production lines since 2010. "This new solution was developed and refined according to Liebherr specifications jointly with a collaborative partner specializing in sensors," said a company spokesperson. "The solution enables picking components from transport bins up to a meter deep."

"We now apply a two-stage triangulation system, where bins containing components are scanned via a process of laser / camera interaction," said Thomas Mattern, Head of Automation Systems Development. This results in significantly improved resolution. "While the previous image recognition system, based on the laser runtime method, was stretched to its limits at 3-5 millimeters accuracy, this new system enables us to achieve ten times the resolution. This also improves recognition of the mini features required for positional identification and component differentiation purposes."

Shadowing and collision risk are also reduced. This allows 8-axis robot arms to pick components, even from transport bins up to a meter deep, such as wire mesh bins or steel bins.

The new image recognition system features a blue laser instead of the earlier red laser. "This captures reflective components more reliably and recognizes organic or semi-transparent materials as well as metal components," said a company spokesperson. "This also makes applications outside the metalworking industry a feasible option."

Speeding up the Entire System

The two-stage triangulation system captures bin content with just one linear movement, without the 3-D vision system having to be positioned beforehand. "Recognition and analysis now take up just five seconds. This facilitates shorter cycle times for the entire system," Mattern explains. This higher resolution means that data cloud surfaces are smooth and practically noise-free. The resultant high-quality readings are transmitted to the bin picking system's main software for further processing. This has also been updated and now features a user-friendly graphical user interface.

For more information contact:

Liebherr Automation

1465 Woodland Drive

Saline, MI 48176

734-429-7225

info.lgt@liebherr.com

www.liebherr.com