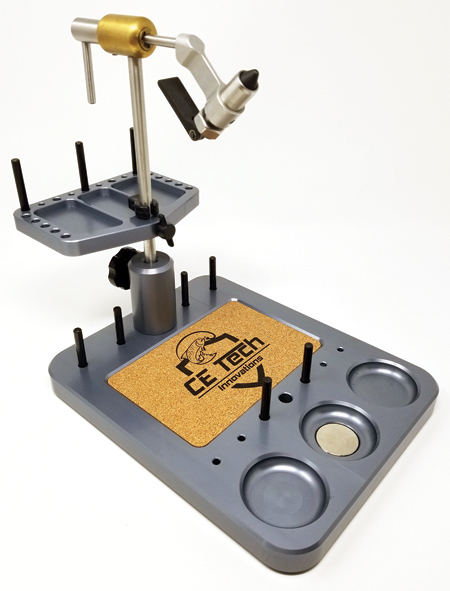

The SCOUT Fly Tying base with an EXPLORER Tool Accessory and fly tying vise attached to the middle post.

CETech Innovation's Guide Tray allows fly tyers to sort their beads, hooks and other materials.

The SCOUT Fly Tying Base's foam centerpiece was designed to hold hooks and tools that otherwise might get lost.

Corey Easter, owner and founder of CETech Innovations, holds a brown trout that was caught on a fly he tied himself on a SCOUT Fly Tying Base.

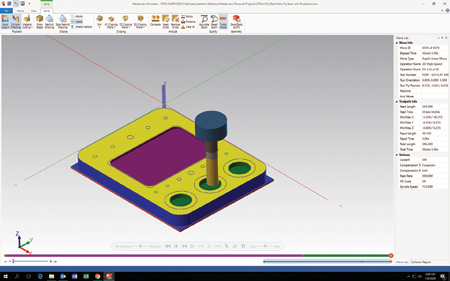

Verify and Backplot running on the SCOUT Fly Tying Base to check for any potential crashes.

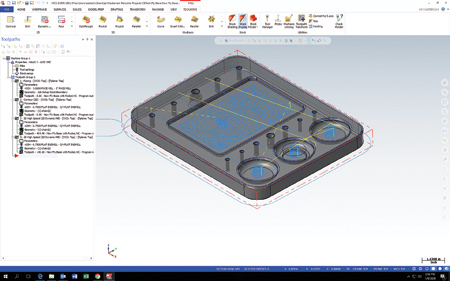

"I went into my office one day and started drawing the base. I drew my wireframe and extruded it and made a solid, and when you make something a solid, it just comes to life," Corey Easter, owner and founder of CETech Innovations.

If you want something done right, do it yourself. At least that is what Corey Easter, an avid fly fisherman and the lead instructor for Surry Community College's Machining Program, believes. As a machinist, Easter has a distinct advantage over his fellow anglers who have to be satisfied with the gear they find in fly shops. When he finds a product lacking, he can make his own. "I wanted something heavy-duty, wide and stable, and there was not anything like it out there," he said of the available fly-tying bases, the tools used to create fly fishing lures, or flies. "I decided to make one myself." Easter's Scout fly tying base was an instant hit with his friends, and he quickly machined a second run for them all. Once Matt Beam, owner and operator of KBD Guides (Sylva, NC), shared the product on his Instagram page and flooded Easter with orders, Easter realized that he had stumbled upon something great.

Easter founded CETech Innovations as a response to the high demand for his fly-tying bases and soon added more products to his online store. Now, CETech offers tool trays, tool caddies and even hunting equipment like gambrels. Easter's products are not just popular within the Appalachian fly-fishing world; they have been picked up by members of the U.S. Fly Fishing Team. Typically, everything is machined from 6061 aluminum on Haas CNC machines at local job shops, but Easter has dreams of growing his own shop in the future.

Although Easter is proud of starting CETech, he said that his favorite part of the entire process was solving the problems he saw in conventional fly-tying bases. "Being a machinist, and having the capabilities of drawing and designing and manufacturing whatever you want, is what makes it fun," he explained. His goal was to make a sturdy base that would not shake or topple as it was being used. "I went into my office one day and started drawing. I drew my wireframe, extruded it and made a solid, and when you make something a solid, it just comes to life." Easter used Mastercam CAD/CAM Software (CNC Software, Inc., Tolland, CT) to design and program his bases, relying on its versatility to turn his vision into a reality.

Easter experimented with different pockets and features, testing his ideas on scrap metal until he had crafted exactly what he wanted. "One of the earlier mistakes I made was trying to make something for me individually that perhaps was not great for everyone," he explained. Easter designed the base to have its post, where the fly being made would rest on a vise, on its left corner. While the design worked perfectly for right-handed fly tiers, it excluded left-handed fly tiers. He was able to make the fix quickly within the software so that his base works for everyone. His finished 5.5 lb. Scout fly tying base has pockets to hold tools and beads, magnets to secure hooks, spool pins to anchor threads and a cork inlay pocket that can hold flies as they dry or for tying tools.

Much of Easter's ability to machine his way through a problem comes from his 15 years of experience in NASCAR research and development manual machining. When Surry Community College offered him a teaching position, he was more than happy to make the switch to complete automation. "I wanted to be doing what was common in the industry," he said. "What is common is CNC, and the software that everyone uses is Mastercam." Mastercam Reseller, Learning Labs, Inc. (Calhoun, GA), provided the college's many seats of the software, and Morganton, NC-based Mastercam Reseller, Barefoot CNC, has been on hand from the very beginning to offer their technical support. "Even though Barefoot's on the industry side, they will always support the education side," said Easter. "I talked to applications engineer Jason Parks and he solved my problem the same day. I have his cell phone number, and if I have a problem, I know he is going to help me. Some of the features Jason has really helped with is Model Prep and Live Tooling. He has helped me figure out how to orient parts and planes in Live Tooling."

Barefoot's ongoing support has allowed Easter not only to teach his students the most efficient machining techniques possible, but it has also given him the tools he needs to grow his business. The Barefoot team introduced Easter to Dynamic Motion technology, which uses sophisticated algorithms to constantly monitor the parent material and to adjust machining to avoid air cuts and gouges at high speeds. "Dynamic toolpaths really help you engage the workpiece and attack it at full depth. It speeds up the process. It all comes down to cycle times. Time is money. I max the spindle speed out. Typically, on the Haas VF-3, if I am running aluminum, I will max the spindle out at 8,000 RPM and feed it 75 or 100 IPM," said Easter.

Knowing that his products will be machined without error gives Easter the peace of mind to focus on innovation. He is always looking for the next way to solve a problem within the fishing industry and often receives requests to make custom gear. "I get people all the time who come as me to do something different for them. I will design it and do a short prototype run with maybe one stick of material. I will send it out to the guy and ask him to use it for a while and then provide feedback for me. Tell me what you like and what you do not like, and that way when we come out with a new product, it is going to be exactly what these guys would like to use."

CETech has grown into a recognized name in the Southern Appalachia fly fishing community, and Easter hopes to continue growing his customer base. He attended the 2019 Smoky Mountain Fly Fishing Festival as an exhibitor and was pleased to see his brand right next to brands known all over the world for their fly-fishing gear. He has plans to attend more events in the future all over the East Coast.

Easter has had some of the largest fly-fishing gear distributors in the country, as well as companies overseas contacting him about carrying his products, but he says that his production is not at that scale yet. "Going forward, I can see getting them into fly shops, but for the time being, I am just selling direct to consumers from the website." At the time of the interview, Easter was focused entirely on putting out his newest products.

For more information contact:

CETech Innovations

www.cetechinnovations.com

CNC Software, Inc.

671 Old Post Road

Tolland, CT 06084

800-228-2877

info@mastercam.com

www.mastercam.com