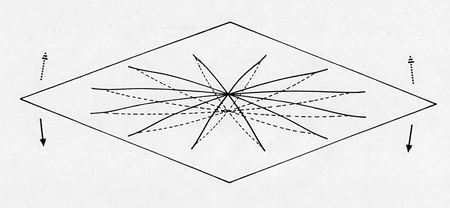

The increment of flexure necessary to collapse and invert a single dome is determined by its structural and material characteristics.

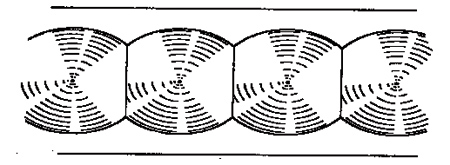

When a row of bistable domes is formed so that their perimeters overlap they create a common dynamic structure along which the flexural forces created by bending can be shared.

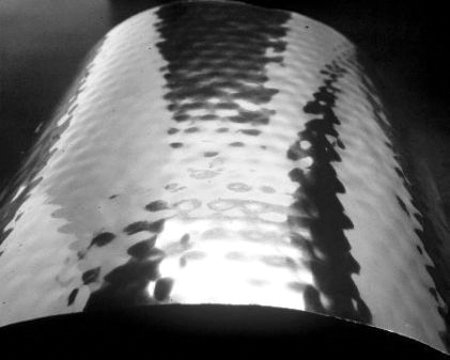

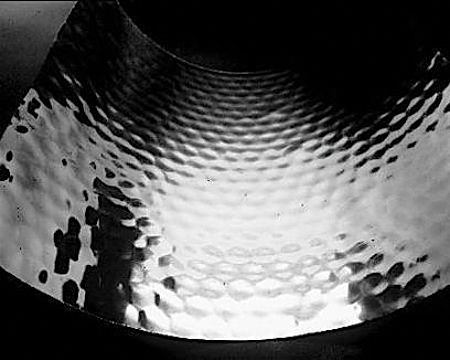

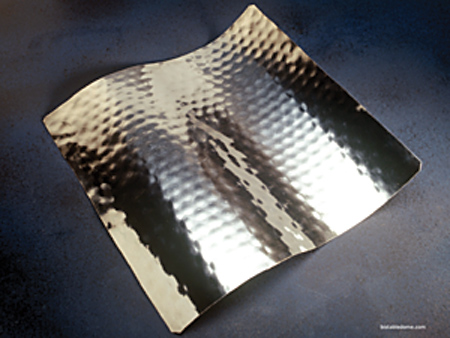

Various versions of the same array of overlapping bistable domes formed in .006-inch high strength 302 stainless steel (similar thickness as a sheet of copy paper)

Climate change is pushing efforts by transportation related industries to transition to thinner stronger and more environmentally friendly steel. One of the problems slowing that transition is springback, which reduces predictability in stamping and can be worse for large radius curvatures common in those applications.

Inventor Paul Ericson suggests that arrays of very shallow overlapping indentations, or domes, might help with springback and expand uses for high strength steel while reducing tooling and prototyping costs. He calls them overlapping bistable domes, or OBDs.

"Closely packed arrays of OBDs can convert tough, paper-thin 302 stainless steel or similar high strength sheet metal into a significantly stiffer adjustable structure that is only a few times thicker in profile than the original material," said Ericson.

OBDs share flexural forces that switch/invert individual domes. When a row of OBDs is formed in a band of material of the same width, the edges of the band buckle slightly between domes and become structurally shorter. The buckling allows dome formation.

Closely packed arrays of OBDs can be formed in thin, hard materials. OBD structures can be used to force flat material into desired curvatures by controlling the characteristics of individual OBDs in formation (height, diameter, bistable tendency, etc.).

Ericson used rows of OBDs in patents for a contact shape digitizing sensor and a pump that pumps when bent.

Ericson explained that OBDs can be stamped with low pressure if they are formed incrementally starting at an edge. "For the sensor and pump, the rows of OBDs were stamped in bands of metal about as wide as the dome diameter," he said. "The edge would buckle slightly near the overlap, functionally shortening the edge relative to the metal through the middle of the dome row, which wants to occupy a larger radius. With arrays of closely packed OBDs, the material deformation is incorporated into subsequently formed OBDs, which can switch sides to compensate."

Adjacent, equally bistable overlapping domes alternate orientation when flattened on one side or the other. When bent, they are forced to the outside of the curvature in numbers proportional to the curvature, stabilizing the new shape. Watch the YouTube video at: https://youtu.be/ANtOyL9--9k

"The same generic OBD array structure can stabilize in multiple curvatures of different radii along different axes," said Ericson. "Managing OBD characteristics, such as bistability bias, dome shape and diameter relative to material thickness, degree of overlap, etc., can be used to create a desired curvature in flat material. If all OBDs have a strong bias for one side, they want to curl into a tube, but a more complex curvature is possible. Bistability can allow the part to be formed and stored flat until needed."

Ericson suggested the possibility of a single machine that could form OBDs with different characteristics and in a wide range of shapes. "Because of the low pressure required, printing tools for forming thin metal OBDs could be made with common 3D printing materials," he said.

Ericson continued, "OBD structures are only functional within minimum radius limits, but may be combined with other metalforming technologies. They may be ideal for the large radius curvature common in auto, boat, train and aerospace related engineering. They may also be useful for storage and containment structures."

Ericson noted that two or more OBD array layers welded or laminated together could reduce the need for framing and bracing. "OBD arrays of different shapes, sizes and bistabilities could be overlapped in layers to produce more complicated curvature," he said. "The flexibility and deformation resistance of OBD structures could be controlled with coatings or glues that manage the ability of domes to switch sides."

For more information contact:

Paul Ericson

Bistabledome.com

505-699-6016

bistabledomes@gmail.com

www.bistabledome.com