Sung Park, Material Processes Engineer at Northrop Grumman, using AM technology to create parts with advanced materials.

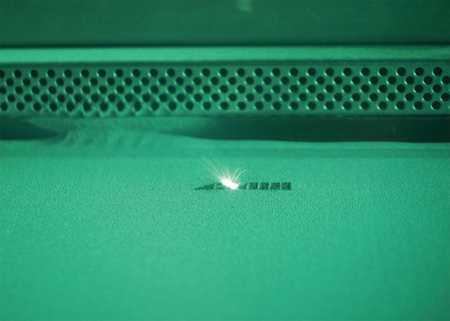

Northrop Grumman reported that it is at the forefront of innovative AM processes. One process, called direct metal laser sintering, uses a laser to melt powdered metal into intricate parts.

"Combined with powerful technology, analysis tools and new materials, Northrop Grumman is reshaping how it approaches design and manufacturing processes, like using 3D printing/additive manufacturing (AM) to support missions in new ways," said Matt Bromberg, Corporate Vice President, Global Operations, Northrop Grumman.

Northrop Grumman has been at the forefront of adopting this design and build method. AM delivers agility, consolidation and savings on lead-times, costs and resources. Products are produced faster and cheaper through its capabilities. Northrop Grumman continues to innovate using AM and has helped facilitate this transformation across several platform-types, ranging from radio frequency sensors, engines, hypersonic weapons and aerospace structures.

3D Printing in Action

From 3D printing rocket motors to using advanced materials to produce aircraft parts, the company uses AM across the enterprise.

Northrop Grumman has also advanced AM applications to space. For NASA's Artemis I mission, Northrop Grumman designed twin solid rocket boosters to propel the Space Launch System (SLS) rocket. In 2020, Northrop Grumman shipped 10 rocket motor segments from Promontory, UT, to the Kennedy Space Center, where the motor segments were assembled into two separate solid rocket boosters. The assembly of these boosters relied in part on 3D printing and computer modeling to modify heritage component designs from the shuttle program and to create new components that are compatible with heritage assembly ones in use.

In 2019, Made In Space (MIS) selected Northrop Grumman to support NASA's Space Technology Mission Directorate (STMD) demonstration of the autonomous robotic manufacturing and assembly platform, Archinaut. The objective of Archinaut's flight demonstration mission is to construct two 10 m solar arrays, on orbit, to power a small Evolved Expendable Launch Vehicle (EELV) Secondary Payload Adapter (ESPA) satellite. Once on orbit, Archinaut will employ its extended structure AM capabilities and advanced robotics to manufacture and assemble the satellite's power generation system.

"Demonstrating AM in space will open up new doors in the design and construction of space structures that to date have been limited by the volume of a launch vehicle," said Richard Stapp, Vice President and CTO, Northrop Grumman. "Effectively building structures in space is one of the next big steps in our continuous journey of space exploration."

Investing in the Transformation of Manufacturing

Northrop Grumman has invested more than $70 million in AM with more than 5,000 AM parts currently integrated into the company's aeronautic platforms, all produced by small- and medium-sized suppliers and partners. The company also currently collaborates with several universities and colleges.

In 2019, Northrop Grumman awarded the U.S. Naval Academy (USNA) Foundation a $150,000 grant to support AM in the Academy's Division of Engineering & Weapons. The grant funded the growth of the USNA MakerSpace, a student-faculty 3D printing laboratory, and its associated engineering programs.

"Advancements in AM are enabling the rapid development of next-generation materials and hardware with reduced life-cycle costs and cycle times to give our warfighters the tactical advantage against emerging threats in complex combat environments," said Larry Ferranto, Vice President, Maritime/Land Systems and Sensors Operations, Northrop Grumman. "Investing in educational programs like this helps to develop critical manufacturing capability in future military leaders and further strengthens our important partnership with the U.S. Navy and Marine Corps."

For more information contact:

Northrop Grumman Corporation

2980 Fairview Park Drive

Falls Church, VA 22042-4511

703-280-2900

www.northropgrumman.com