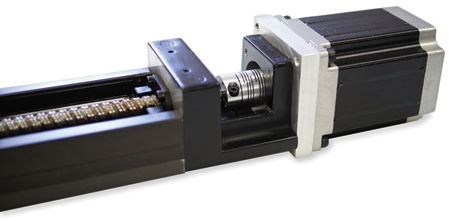

Servo motor coupled to a lead screw with a zero-backlash coupling for precise motion control.

Ruland offers beam couplings for robotic applications. The beam couplings are machined from a single piece of aluminum or stainless steel with several spiral cuts for higher torsional stiffness and torque capabilities than single beam couplings. The multiple-beam pattern allows Ruland couplings to accommodate higher amounts of parallel misalignment than single beam couplings, while also allowing for high angular misalignment and axial motion.

"Medical and surgical robots often combine a stepper or servo motor to a lead screw or encoder requiring a zero-backlash coupling for precise motion control," said a company spokesperson. "These systems have limited torque requirements; however, they may need high responsiveness and flexibility making a beam coupling a suitable choice." Ruland's four-beam style couplings (P- and MW-series) have a more compact design that is paired best with light-duty applications such as servo motor to encoder connections. The six-beam style coupling (F-series) has increased torque capacity and is suited for light-duty power transmission applications such as connecting a motor to a lead screw.

Ruland multiple-beam couplings are manufactured with a balanced design for reduced vibration at speeds up to 6,000 RPM. Clamp-style F-series couplings are supplied with Ruland's proprietary Nypatch anti-vibration coating. Nypatch helps ensure that the hardware stays in place through intense vibration and movements over time whereas untreated hardware may back out from harsh vibrations.

Ruland beam couplings are offered in clamp and set screw styles with inch, metric and inch to metric bore combinations ranging from 3/32" (3 mm) to 3/4" (20 mm). They are available in 7075 aluminum for lightweight and low inertia or 303 stainless steel for higher torque and torsional stiffness. Special designs such as anodizing, nonstandard bore sizes and special tolerances are available upon request.

All Ruland zero-backlash beam couplings are manufactured from select North American bar stock in Ruland's factory in Marlborough, MA, under strict controls using proprietary processes. Full product information, 2D and 3D CAD files, installation videos and more are available on ruland.com.

For more information contact:

Ruland Manufacturing Co., Inc.

6 Hayes Memorial Drive

Marlborough, MA 01752

508-485-1000 / 800-225-4234

ruland.com

www.ruland.com