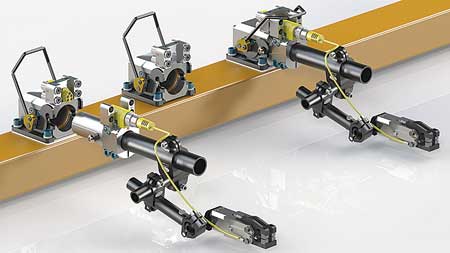

DE-STA-CO offers the Accelerate Collection, a standard line of light end effectors.

"The DE-STA-CO Accelerate Collection of lightweight tooling features end effectors that are up to 50% lighter than others, providing automated pressroom stamping line productivity improvements of 25 to 30%," said a company spokesperson.

DE-STA-CO has introduced the Accelerate Collection of lightweight tooling designed for faster and more efficient automated pressroom stamping lines.

"Our customers told us that they need to increase their production speeds in order to stay competitive," said Rob Pitera, DE-STA-CO Global Product Director for end effectors. "But you can not just speed up a line that is equipped with traditional components, because the tools will bounce and put undue stress on the automation, leading to greater wear and tear and machine downtime. To meet our customers' productivity needs, we designed an all-new line of end effectors that are up to 50% lighter than their predecessors. The components' lighter weight translates into production line speed gains of 25 to 30%."

Since workers manually change tooling on many automated lines, Accelerate end effectors' lighter weight also improves ergonomics, resulting in higher worker safety ratings.

"DE-STA-CO product designers started with high-strength aircraft-grade aluminum in order to reduce clamping wall thickness and overall weight, without sacrificing strength," said a company spokesperson. "This approach also eliminated the need to use more expensive, longer-lead-time materials like carbon fiber, for a more cost-effective solution.

"Accelerate components also have trimmer, more elegant shapes than their predecessors. Greater flexibility provided by CNC machines, tooling and fixtures let DE-STA-CO contour the components to eliminate unnecessary bulkiness and weight. Further weight savings come from specifying thin-wall extruded tube for Accelerate end effector frames instead of heavier solid bars or thicker wall tubing."

The Accelerate Collection is modular and completely customizable. Although its components are lighter than others, they are sized to global standards, making them compatible with existing equipment, regardless of brand.

For more information contact:

DE-STA-CO

1025 Doris Rd.

Auburn Hills, MI 48326-2614

888-337-8226

marketing@destaco.com

www.destaco.com