The connecting rods are carried to the machine via a conveyor belt. The workpiece carrier wheel constantly rotates and guides the blanks to the vertical grinding wheels arranged with parallel faces. The end faces of the connecting rods are machined synchronously and the intelligent measuring systems provide ideal end dimensions. Once fully machined, the connecting rod is conveyed hanging from the unloading rail and then cleaned before traveling along a conveyor belt to the next station on the production line.

The conveyor belts bring a new level of automation to the loading and unloading processes in production.

Precision workpiece carrier wheel. Recesses are tailored to the workpiece for precise double surface grinding of the connecting rods.

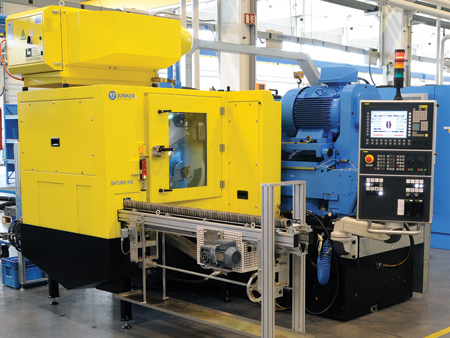

By means of a continuous grinding process, the SATURN machines connecting rods measuring up to 400 mm in length.

As a globally operational partner to the automotive sector, Canadian company Linamar develops and manufactures components and systems for drive solutions from more than 60 locations around the world. The 23,000 sq. m Linamar Powertrain GmbH plant in Crimmitschau, Saxony, was established in 2010 and produces engine components such as connecting rods and transfer gears for all-wheel drive vehicles.

The connecting rods that are machined on the SATURN 915 are primarily used in gasoline and diesel engines of between one and three liters in size. André Schmiedel, Operations Manager for Linamar Powertrain GmbH, explained: "We have a total of six production lines installed, which can produce in excess of 11 million connecting rods each year. These are machined or even fully assembled in line with the OEM's requirements and drawing specifications."

Efficient Machining

By means of a continuous grinding process, the SATURN machines connecting rods measuring up to 400 mm in length. The connecting rods are carried to the machine via a conveyor belt. The workpiece carrier wheel constantly rotates and guides the blanks to the vertical grinding wheels arranged with parallel faces. The end faces of the connecting rods are machined synchronously and the intelligent measuring systems provide ideal end dimensions.

"The SATURN grinding machine meets the OEM's requirements in terms of parallelism, planarity and surface roughness with precision," said Schmiedel. "This grinding technology is a cost-effective and efficient process."

Once fully machined, the connecting rod is conveyed hanging from the unloading rail, and then cleaned before traveling along a conveyor belt to the next station on the production line.

Flexible Applications

With the SATURN double surface grinding machine from JUNKER, plane-parallel workpieces of wide-ranging shapes and geometries can be machined efficiently. Besides connecting rods, these workpieces include rolling elements, rings, universal joints, cams, needle cages or ball cages, pistons, coupling components and stamped parts of every kind. The segments that pick up different types of workpiece are quick and easy to change. The grinding machine is also particularly suited to machining heavy workpieces, such as valve plates, bearing housings and pump housings. The SATURN is capable of processing various materials. For instance, Linamar uses it with not only micro alloyed steels but also sintered metal.

As Schmiedel explained, "With the SATURN, we have a high-performance grinding machine that enables us to offer our OEM companies excellent availability while also ensuring the tolerances are observed at all times. The JUNKER grinding machine is flexible, and it can quickly be converted to accommodate new requirements. The efficiency of minimal service expenditure combined with consistently high quality results has never failed to impress us."

For more information contact:

Erwin Junker Machinery, Inc.

2541 Technology Drive, #410

Elgin, IL 60124

847-488-0406

info@junker-usa.com

www.junker-group.com