Operose employee activating pallets to run overnight.

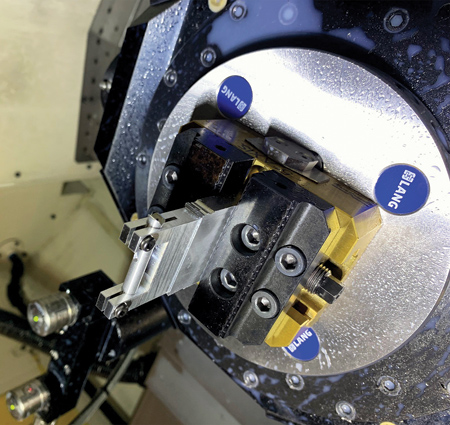

Rotary table

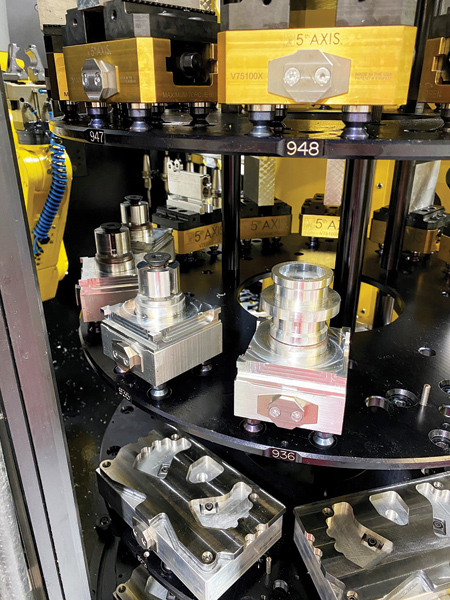

"That is what made me decide to go with the Plus-K, solely having the ability to load it up and go do something else," Stilson said. "The ability to have 60 tools and 60 pallets is pretty appealing."

The RoboDrill Plus-K 60 measures only 32" wide, making it the perfect fit for Stilson's shop.

Operose can handle complex machining jobs, from prototyping to large-scale production runs, and most metals.

Growing a machine shop takes vision, and Tyler Stilson's eyesight is 20/20. His job shop, Operose Manufacturing in Frederick, CO, can produce anything from fluid control mechanisms to sporting goods. They can handle complex machining jobs, from prototyping to large-scale production runs, and most metals.

But it did not start that way. When Stilson founded the company in 2007, he had one mill and one lathe. However, he had big ideas and aspirations. He wanted to reinvent the way job shop manufacturing works.

"The idea was to change the way we process parts," Stilson said. "In the standard manufacturing MO, there were a lot of times where you set up the first operation and run 50 parts, set up the second operation and run 50 parts, and then when you get to the third operation you realize there was a mistake on the first operation because the part was not complete."

By 2010, he knew he needed to get into 5-axis machining. At the time, they were manufacturing parts with intricate features on different angles. That required offsets, small-tapped holes, winding toolpaths and careful workholding strategies.

There were also many questions. He was not familiar with 5-axis programming or software. He was not sure if he needed simultaneous 5-axis machining or if 3+2 was the right choice.

So, he reached out to some old friends at Methods Machine Tools. Stilson used to interact with Methods' service and application teams at his uncle's shop, a 35-person facility where he managed most day-to-day operations and where he first encountered the RoboDrill.

"We researched a lot on our own," Stilson said of 5-axis machining. "We also relied on Darren Wall, a Sales Engineer working out of Methods' Phoenix Technical Center. We told him what we wanted to do and he showed us how to do it."

One of the shop's first forays into next-level technology came in the form of a rotary table on an existing RoboDrill. "Getting at the parts with a 5-axis machine was incredible-we saw huge opportunities to save money and improve our quality. Less than two weeks afterwards, every single one of us reached the same conclusion: we needed to figure out how to do this again," he said.

Operose installed a second rotary table in 2012 and the company soon developed its own product line of barbells and barbell collars, which proved so profitable the job soon took up 60% of the shop's capacity.

Moving into Multitasking

Now tasked with meeting the demands of high-volume production, the company purchased a Nakamura-Tome Super NTMX, a multitasking machine that provides the capability of a 5-axis machine and the reliable throughput of a lathe. Operose was another step closer to automation and was now equipped with new machining capabilities such as a tool spindle, lower turret and 72 tool stations.

"Being able to get more sides done with less handling made an incredible impact on our shop. It was a big leap," Stilson said of the job.

The shop began to grow in terms of size and capability. Operose acquired a second shop, 3D-CNC, in Hutchinson, MN, and started a testing environment for machinery and automation at his home. He became comfortable with more complex technology, such as 3+2 machining and multitasking, and immediately realized the benefits of hands-off machining.

Next Stop: Lights-out Automation

In the fall of 2019, Stilson began looking to test out equipment at the workshop in Mankato. Since it was his at-home lab, he needed the ability to load up a cell in the morning and collect perfect parts at the end of the day.

Given the size of the workshop and his preference for RoboDrill's ease of use and adaptability, he selected the RoboDrill Plus-K.

The system measures only 32" wide, making it the perfect fit for Stilson's shop. Methods enabled the robot to recognize a standard feature on the quick-change carrier, so there was no need to program the robot.

"That is what made me decide to go with the Plus-K, solely having the ability to load it up and go do something else," he said. "I know RoboDrills. The ability to have 60 tools and 60 pallets is pretty appealing."

The first system was installed in Mankato in April 2020. The second followed in the Colorado Shop in January of 2021 and the third followed soon after. They mainly produce aerospace and medical parts made from stainless steel or aluminum.

In the long term, Stilson wants to hit specific revenue goals as well as utilization rates on wire and EDM machines. While his figures are aggressive, Stilson believes he can utilize the Plus-K to prove out concepts in the Mankato workshop and then scale up operations in Operose's Hutchinson, MN, and Frederick, CO, shops.

"Part of what made the system stand out was the footprint," he said. "I do not know how thick my floor is in Mankato, and there are other unknowns. What I do know is that if I want to add more, they will fit in the shop. And I know people can use one machine, one control and become extremely productive."

Stilson continued, "The Plus-K is a much better system because it has 5 axes and 60 tools," he said. "The pallet management system on it takes about 15 minutes to learn inside and out." Using machine monitoring software, Stilson is able to track how the Plus-K systems perform. "I have run a lot of other parts on it that I would squeeze in during the day," he said. "Anytime that I was not actively setting up or running another job, I would turn on these parts. The machine was never sitting idle."

Continuous Production, Continuous Growth

There are other ways Methods' has helped Operose become more productive, Stilson said.

Stilson recalled an issue that occurred on an older machine in 2010. It was the weekend, and the chances of getting the machine back up and running quickly were slim. Nevertheless, he wanted to keep the issue at the forefront of his mind, so he notified his Methods technician. About 20 minutes later, the field service technician pulled up to Operose.

"Within an hour, on a Saturday afternoon, I was back up and running," Stilson said. "You do not get that kind of service, typically. It was not the only time I had an experience like that with Methods."

Operose has grown exponentially since implementing a rotary table more than a decade ago. Due to lights-out automation and 5-axis technology, Operose can approach traditional job shop work with a more competitive edge and take on medium-volume production runs.

For Methods' part, Wall said he is grateful to work alongside such a forward-thinking, automation-friendly shop: "Tyler sees these new technologies, realizes what he has to do to stay competitive and finds a great way to implement them. He is separating himself from much of the competition with his 5-axis and automation capabilities."

For more information contact:

Operose Manufacturing

3762 Imperial Street, Unit A

Frederick, CO 80516

303-833-5967

info@operosemfg.com

www.operosemfg.com

Methods Machine Tools, Inc.

65 Union Avenue

Sudbury, MA 01776

877-MMT-4CNC (877-668-4262)

www.methodsmachine.com