SmartPAC PRO (left) featuring new ProCamPAC PRO advanced Programmable Limit Switch, and ShopFloorConnect (right) featuring the new PM Tracker for efficient machine preventative maintenance tracking.

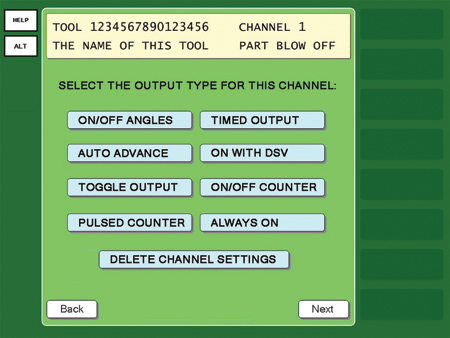

New ProCamPAC PRO Cam Output Menu showing new cam types.

Wintriss Controls Group has announced it will be demonstrating new, advanced features in its SmartPAC PRO Press Automation Controller and its ShopFloorConnect OEE and Data Collection Software at FABTECH booth B5716. For a connection to a smarter factory, including when remote monitoring is required, the latest functionality in SmartPAC PRO and ShopFloorConnect gives fabricators and metal formers efficient and easy-to-use tools.

"Wintriss has developed the world's most advanced Programmable Limit Switch (PLS), ProCamPAC PRO, for its flagship SmartPAC PRO Press Automation Controller," said a company spokesperson. "FABTECH attendees can see this new PLS which includes counter driven outputs that operate only on specified strokes to precisely control gagging operations, new asymmetrical toggle outputs for controlling complex configurable tooling and additional timed outputs for even greater versatility."

A new Toggle Cam Output performs an asymmetrical toggle function, turning an output off or on for different stroke amounts. The output can be used to operate diverter gates and to control complex gagging operations. The new On/Off Counter Cam Output precisely controls functions that need to operate at a preset interval instead of on every machine cycle. Operating similarly, a new Pulsed Counter Cam Output is programmed with an "on angle" and a dwell time instead of an on-off output.

Useful when running configurable tooling, a new Channel Always On Cam Output will simply turn on and stay on until a new tool is loaded. The ProCamPAC PRO PLS also features a Triggered Cam Output that actuates a precision one-time cam timing signal based on a preset trigger, such as an external input from ancillary equipment, an extended period of machine idle time or a job change. This output type is suited for diverting parts during a warm-up period, QC checks or when bad parts are determined by an outside measuring system.

Attendees can also see new Advanced DiProPAC available on the SmartPAC PRO Press Automation Controller, which features over 10 new capabilities for even greater die protection for presses. Highlights include a new customizable green sensor type called Green Flex that combines all the elements of the other Green sensor types. This versatile cyclic sensor can monitor intermittent events such as gagging operations, and also has a function that allows for the precise monitoring of events that need to occur multiple times per press cycle.

In addition, Wintriss has expanded the static sensor monitoring capabilities in DiProPAC with auto-reset, programmable bypass angles and minimum actuation time settings.

Also to be highlighted at FABTECH, Advanced ShopFloorConnect OEE and Data Collection Software collects downtime and production efficiency data from every machine, ranging from CNC machines to presses, fabricating machines and more, in all areas of discrete manufacturing. Data is displayed in real time, and indispensable manufacturing reports are produced, including detailed OEE reports in a variety of formats. Wintriss will showcase the new ShopFloorConnect PM Tracker, which enables users to track important machine preventative maintenance (PM) items by run-hours or machine cycles, issues targeted alerts when an item requires PM and tracks the maintenance work history for all machines.

ShopFloorConnect 6.0 also features a new Universal Interactive Application Program Interface (API) that enables users to quickly set up two-way data sharing with any ERP or MES software.

For more information contact:

Wintriss Controls Group

100 Discovery Way, Unit 110

Acton, MA 01720

800-586-TECH

www.wintriss.com

www.shopfloorconnect.com

FABTECH Booth B5716