VERICUT 8.0 streamlines the NC validation workflow

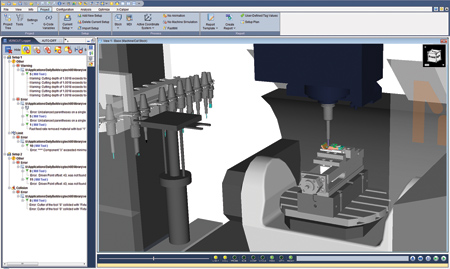

VERICUT CNC machine simulation, verification and optimization software simulates all types of CNC machining, including drilling and trimming of composite parts, waterjet, riveting, robots, mill/turn and parallel kinematics. The software operates independently, but can also be integrated with leading CAM systems.

VERICUT Machine simulation detects collisions and near-misses between all machine tool components such as axis slides, heads, turrets, rotary tables, spindles, tool changers, fixtures, workpieces, cutting tools and other user-defined objects. Users can also set up `near-miss zones' around components to check for close calls and detect over-travel errors. Machine movements and material replacement can even be simulated while stepping or playing backwards.

New Ribbon Bar

The VERICUT 8's new Ribbon Bar allows users to quickly select the VERICUT function they want to use. As the user moves from tab to tab, the Ribbon bar dynamically updates to show the options available for that tab. Options are grouped by the function they perform within VERICUT.

"VERICUT 8 is all about optimizing our customers' workflow to quickly access only the menu choices needed at the time," said VERICUT Product Specialist Tom Benedetti. "The Ribbon Bar helps users find the functionality they need quickly and with minimal mouse clicks."

The Ribbon Bar is highly customizable, but to ease the transition for existing users, a "VERICUT Classic" setting organizes all of the menus and options where users previously found them. Several other layout options are included and can be selected depending on the task at hand. Users can also create and save their own layouts as needed for different jobs.

Integration with Cutting Tool Suppliers and Tool Management Systems

As with all software programs, the accuracy of the data input will directly affect the output. So, an accurate model of the cutting tool and holder is required for the effective and accurate simulation of the machining process. Leading cutting tool manufacturers, such as Sandvik, Kennametal and Iscar, now make 3-D solid model data available and VERICUT can read in this model data for use in the simulation process. Many of the 3-D models are available via the Machining Cloud App, and version 8 has been enhanced to take advantage of more Machining Cloud metadata. This can significantly simplify the configuration of tools for use in VERICUT. VERICUT also interfaces with tool management systems such as TDM Systems, Zoller, and WinTool for access to databases storing cutting tool information. Pre-setting suppliers including Zoller and Speroni can also interface to the software, so tool offsets and exact dimensions can be applied to the simulation process.

Consolidated Reporting Features

=The VERICUT logger now displays messages and reports from many sources. In addition errors, warnings and other messages from the VERICUT session, it also displays information from AUTO-DIFF and X-Caliper. The messages can be grouped, sorted and displayed in a variety of ways depending on user preference.

Force Enhancements

The Force module is a physics-based optimization method that determines the maximum reliable feedrate for a given cutting condition based on four factors: force on the cutter, spindle power, maximum chip thickness and maximum allowable feedrate. In version 8 there are new features to account for entry/exit speeds, "clean-up" feedrates and tooling information has been rearranged to be more intuitive.

Model Manipulation Simplified

The ability to translate models using features eliminates the need to create coordinate systems for positional information.

Graphical Tool Path Analysis

A new "Toolpath Trace" feature creates a wireframe of the motion path that can then be measured. No stock model is needed to generate a path. Picking on a path in the wireframe automatically sets the simulation to the current line in the NC program.

Control Panel Emulator

Companies and schools can train future CNC machine tool operators using a graphical user interface that looks just like the real control. The virtual machine responds just as the real machine would.

Simulation of All Types of Machine Tool Brands

CGTech has worked with end users and machine tool manufacturers to create accurate and effective Virtual Machine Tool configurations. These range from simple 3-axis milling machines to multi-axis machining centers; simple 2-axis lathes to complex mill-turn centers with sub-spindles and robot loading; waterjet and laser cutting and machining/polishing robots.

VERICUT simulates every machine tool brand, including DMG MORI, Mazak, Makino, Matsuura, Hermle, Chiron, Starrag, WFL, Nakamura-Tome and many more.

Other Products

With the growth of the various additive manufacturing processes, CGTech has developed programming and simulation of the CNC processes used in this technology area, including automated composite fiber-placement and tape-laying.

For more information contact:

CGTech

9000 Research Dr.

Irvine, CA 92618-4214

949-753-1050

info@cgtech.com

www.cgtech.com

IMTS booth E-3346