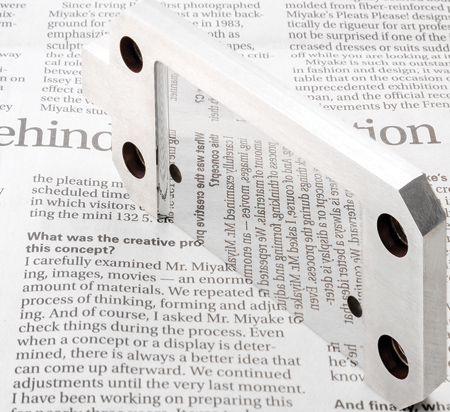

OPM250L front

Part finished in one process

Complex molds with conformal cooling and deep, finished ribs

Machine tool manufacturer Sodick has announced the release of the OPM250L, an additive metal 3-D printer that incorporates high speed milling into the same workspace, allowing for single-process production of finished components. "Sodick enters a new product category with the new machine, and Sodick believes 3-D printing is an ideal complement to its current offerings," said a company spokesperson. "Though the OPM250L continues to incorporate Sodick's characteristic rigid linear motors and motion control technology, the additive machine is Sodick's first foray into direct metal laser sintering (DMLS) technology." The OPM250L is primarily aimed at mold makers, as the ability to create conformal cooling channels within a finished mold can improve mold performance by reducing cooling time, deformation and cycle time.

"Sodick's OPM250L offers the ability to machine workpieces before printing is complete, with alternating passes of laser sintering and milling," said the spokesperson. "This cannot be accomplished on traditional 3-D printers, which require extended finishing processes after printing." In addition to producing conformal cooling channels, this technology also makes it possible to reduce the number of parts necessary to produce a mold, in some instances reducing a mold from 21 pieces to just one. Due to the demands of such a fully integrated machine, Sodick has developed a dedicated CAM system, Z-Asso, capable of importing CAD data, generating laser and machining data, optimizing cutting along high-load areas and simulating the process to accurately estimate production time.

The fully integrated one-process machine further achieves process improvements, allowing for unmanned and remote machining. "Designed for compatibility with the Internet of Things (IoT), Sodick's unmanned OPM250L may be operated remotely in a way that would be difficult if not impossible to achieve through methods involving multiple machine tools. Through more integrated technology and a more streamlined work process, Sodick believes that the OPM250L improves all major areas of concern for mold manufacturers, from lead time to production cost to mold performance," said the spokesperson.

For more information contact:

Sodick Inc.

1605 N. Penny Lane

Schaumburg, IL 60173

847-310-9000 / 888-639-2325

info@sodick.com

www.sodick.com

IMTS 2016 Booth E-4802