CT Scanning Used to Validate E-Lock Wiring Bobbin Postion

September 1, 2016

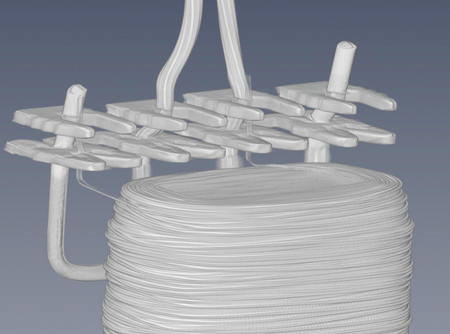

Scans of wire bobbin, showing precise path taken by 0.008" diameter wires inside; scan completed after final assembly of the unit

Exact Metrology, working at the company's Brookfield, WI, location, has successfully used its ProCon industrial CT scanning technology to validate the position of a wire configuration in the bobbin of an electronic lock assembly for one of its customers.

As technician Sean Plastine explains, "A customer came to us to verify the position of a 0.008 inch diameter wire inside its electronic lock assembly. The position of the wire could not previously be verified while the components of the lock were being assembled. Inspection of the wire bobbin after assembly was also impossible."

By using its CT scanning technology on the completed lock assembly, Exact technicians were able to determine the wire's precise position without the need for disassembly or other compromise on the finished article. Any deviation of the wire's nominal position could be noted, allowing for subsequent changes in the assembly protocol as needed.

Plastine added, "We are very excited by the possibilities of this technology. It is opening new doors for our contract services."

Exact Metrology is an ISO 9001:2008 and AS9100 Certified Company.

For more information contact:

Dean Solberg

President

Exact Metrology

20515 Industry Avenue

Brookfield, WI 53045

262-533-0800 / 866-722-2600

deans@exactmetrolgy.com

www.exactmetrology.com

< back