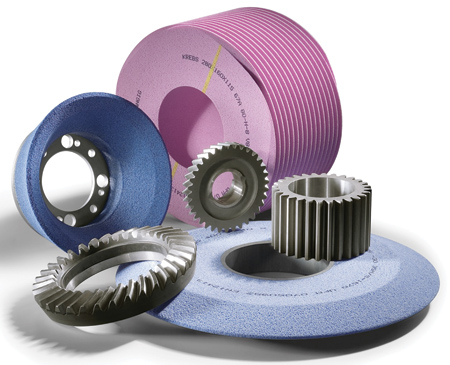

Ceramic bonded CBN and diamond tools.

Investments regarding the expansion of the factory and in sustainability management are currently being planned.

Solutions for profile grinding, continuous generating grinding applications.

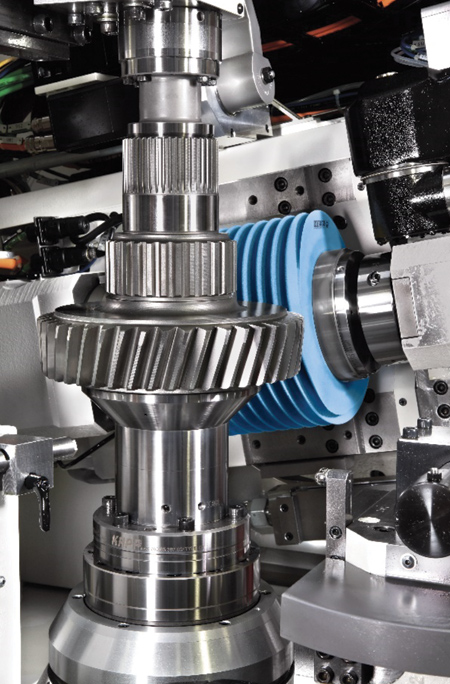

Continuous generating grinding with fine and polishing zone (picture courtesy of Kapp-Niles)

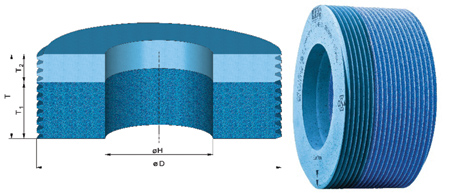

Re-coatable CBN grinding wheel with a carbon base body.

The cornerstone of the Krebs & Riedel grinding wheel factory in Bad Karlshafen, Germany, was laid some 125 years ago. Today the family-owned company operates worldwide as a manufacturer of precision grinding wheels for the automotive, aerospace, mechanical engineering, medical technology and wind power sectors. Krebs & Riedel has subsidiaries in China and India and a distribution network in more than 30 countries.

In addition to conventional grinding wheels, cutting wheels, cup grinding wheels and grinding segments with ceramic and synthetic resin bonds, Krebs & Riedel also manufactures CBN and diamond tools with ceramic bonds as well as honing rings. Krebs & Riedel grinding wheels are used on grinding machines such as Gleason, Kapp-Niles, Klingelnberg, Liebherr, Mitsubishi, Reishauer and Samputensili.

"Krebs & Riedel relies on extensive R&D and works closely with several research institutions, and also invests in sustainability management," said a company spokesperson.

The product lineup includes corundum and silicon carbide wheels with a ceramic bond and synthetic resin bond for most industrial grinding applications up to 900 mm O.D. for round, flat, tool, centerless, gear and rough grinding applications. Cut-off wheels in synthetic resin bond with and without fiber reinforcement produce up to 800 mm O.D. for chop cut, pendulum cutting and rotary cutting.

Additional solutions include: roughing and pendulum grinding with and without fiber reinforcement for the cleaning shop and the foundry industry; grinding wheels for pendulum grinding machines; grinding wheels for bench grinders; grinding wheels for grinding manipulators; and diamond and CBN grinding media in vitrified bond with a working speed of up to 200 m/s for internal, flat, circular, tool grinding and special grinding processes.

Additional product highlights include Blue Moon wheels for continuous generating grinding; a wide range of dressable grinding worms with a ceramic bond for gear machining; and re-coatable CBN worm grinding wheels on a carbon carrier.

For more information contact:

Krebs & Riedel

Schleifscheibenfabrik GmbH & Co. KG

mail@krebs-riedel.de

www.krebs-riedel.de