Jörg Haar, Production Manager, TLS Anilox GmbH, Salzkotten, Germany, with the new FERMAT BHC 63/4000 CNC Cylindrical Grinder.

The FERMAT BHC 63/4000 Cylindrical Grinder has the capacity for 4,000 mm length workpieces.

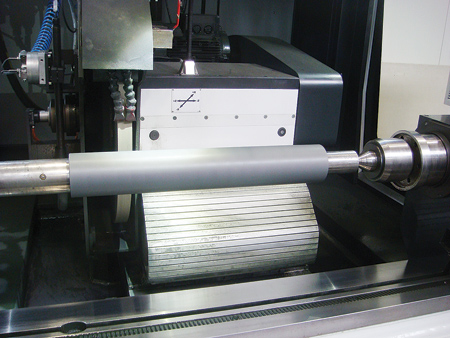

At TLS Anilox a diamond grinding wheel is used to grind the ceramic coated printing roller surfaces.

At TLS Anilox a Flexo printing roller surface is ground to a perfectly cylindrical shape. The long printing rollers are used for printing on corrugated material.

"Requests were coming in for larger, longer printer rollers. The corrugated industry requires longer rollers. In order to fulfill our customer's request, we had to have a larger grinder capacity," said Jörg Haar, Production Manager, TLS Anilox GmbH. "We required a larger machine for 4,000 mm length rollers. Our current FERMAT grinder could only do up to 3,000 mm length."

"It is important to have perfectly cylindrical rollers manufactured for the printing industry, therefore the grinding machine used to make it perfect needs to be stable and grind with precision," said Haar.

With the need for a longer capacity cylindrical grinder, TLS Anilox chose to purchase another FERMAT grinder. TLS Anilox GmbH, Salzkotten, Germany, manufactures rollers of all sizes for the printing industry. TLS Anilox already had one FERMAT Universal BUB E 32/40/50 CNC Cylindrical Grinder and its plant in Langenfeld, Germany, had several FERMAT grinders of various sizes.

"The FERMAT grinders we use throughout our company have produced quality parts and have served us well with low maintenance," said Haar. "Management and operators are familiar with the machines and the controls."

The FERMAT BHC 63/4000 CNC was installed at TLS Anilox in 2015. It has a 4,000 mm length capacity and 4,000 kg weight capacity. "The cylindrical grinder was just what we needed to fill the new orders for longer rolls," said Haar.

The FERMAT BHC 63/4000 CNC has a Siemens 840D sl control for longitudinal and plunge-cut grinding of cylindrical and conical external surfaces. Internal grinding can be performed with an internal grinding attachment. Grinding of face surfaces can be performed by the side of the grinding wheel or its circumferential surface by swiveling the work head. It has a controlled X-axis which is the grinding wheel infeed, and Z-axis which is the table feed.

Tolerances of IT4 and higher are possible and surface roughness of Ra 0.2. The mated moving surfaces are hand scraped and coated with Teflon to reduce friction. The casting is ribbed for stability. The machine can be equipped with a dust removal system. TLS Anilox uses its own method of dust removal. Hand wheels can be used for X-axis and Z-axis setting. The cover doors are manually controlled.

The rollers made by TLS Anilox are especially for the flexo printer. Flexography (often abbreviated to flexo) is a form of printing process that utilizes a flexible relief plate. It is essentially a modern version of letterpress which can be used for printing on almost any type of substrate, including plastic, metallic films, cellophane, corrugated cardboard and paper. "These rollers determine how much color will be printed on the plastic bag or corrugated material," said Haar. "A special ceramic surface is created on the roller and our FERMAT Cylindrical Grinders grind the surface to a perfect diameter."

"First, the roller is coated with ceramic at a shop near TLS Anilox. Then after we receive it, only a small amount of ceramic is removed in the grinding process. The roller is dried first. Grinding is performed to make the diameter cylindrically perfect. With the FERMAT grinder we can adjust the speed of the workpiece in very small increments to make the diameter cylindrically perfect. We perform another process on the surface after the grinding," said Haar.

TLS Anilox uses a diamond wheel on its BHC 63/4000 CNC Grinder because it is machining ceramic, a very difficult material to grind. To change the grinding wheel requires opening the machine and using a crane to remove and replace the grinding wheel. The grinding wheel only needs to be changed approximately once a year.

When grinding ceramic that has porosity, a lot of dust is created. It is important to keep the dust from remaining on the roller. TLS uses a cleaning system for the grinding water so the grinding dust does not stay on the roller. TLS does not need the dust removal system that FERMAT can provide because it grinds with low speed. A special coolant and cleaning system is used. The machine is provided with special paper filters. Some machines are equipped with magnetic filters when grinding metal. The cleaning system has two pipes. One carries the dirty water out to the cleaning system where the ceramic fines are removed. Another pipe brings in the clean water. Because of the porosity of the ceramic no dust can be left on the surface.

TLS Anilox runs two shifts. It is possible for one operator to run both FERMAT machines. While one machine is running the other machine is being set up for the next workpiece. It takes several hours for the full grind cycle.

"We did not require training because we already had the FERMAT Universal BUB 23/40/50 CNC Grinder," said Haar. "That is one of the reasons we wanted to purchase another FERMAT grinder."

"Maintenance has been low on the FERMAT grinders. I feel that regular maintenance is very important to prevent big problems later. If you have a small problem you will be able to see it when you perform regular scheduled maintenance. A company's financial management may say scheduled maintenance is too expensive but I believe it is required on an annual basis and saves money in the long run," said Haar.

TLS Anilox decided to build its new plant in Salzkotten because the personnel that had the knowledge to grind the printing rollers and other components lived in the Salzkotten vicinity. The factory was built in October 2014 and by November 2014 rollers were being produced on the first FERMAT grinder. Seventeen people are employed at this location currently. Some older grinders are also used at the location to grind the old ceramic coatings off and prepare them again for a new surface.

The rollers are exported worldwide and are manufactured in many sizes from a small label printer to a very large roller for corrugated material. With the new FERMAT BHC 63/4000 CNC Cylindrical Grinder, TLS Anilox has the capacity to grind perfectly cylindrical rollers in the longer 4,000 mm length.

For more information contact:

Paul Mandelbaum

National Sales Manager

Lucas, A FERMAT Group Company

13020 St. Clair Ave.

Cleveland, OH 44108-2033

216-451-5588

paulm@lucasprecision.com

FERMAT.sales@lucasprecision.com

www.lucasprecision.com

FERMAT Machinery

Prumyslova 11

102 19 Prague 10

Czech Republic

export@fermat-machinery.com

www.fermatmachinetool.com