InfiniteFocus by Alicona is used for the high-resolution measurement of both ground surfaces and abrasives.

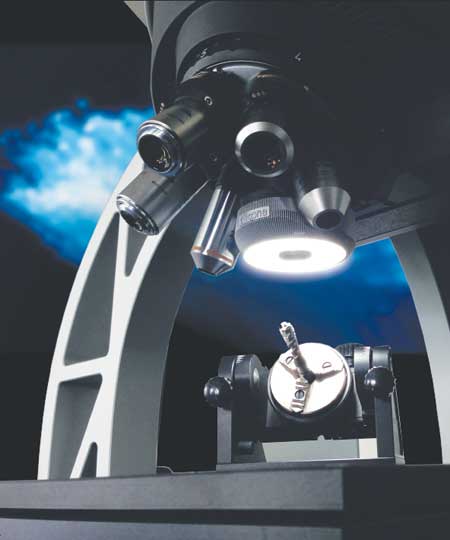

"A ring light achieves diffuse illumination," said an Alicona spokesperson. "This enables users to precisely measure surfaces with varying reflection properties."

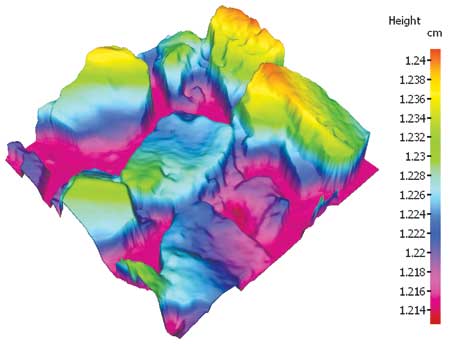

3D measurement of an abrasive in registered color and pseudo color visualization is shown. Measurements show how grain structure and grain size correspond to machining results.

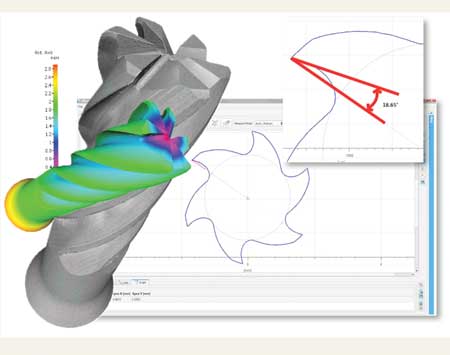

Optical 3D cutting edge measurement with Alicona: The technology of Focus-Variation is used to measure deburred, ground, smoothed, polished tools and workpieces.

"Performance, precision and tool life depend, amongst other factors, on the accuracy of the grinding process as well as the abrasive used for edge rounding," said an Alicona spokesperson. "In order to give the edge its perfect geometry, it is deburred, smoothed, polished and cleaned. The quality of a cutting edge, however, corresponds to the quality of the grinding process and the surface condition of the abrasive used for edge preparation. When it comes to quality assurance, machine manufacturers using grinding procedures - such as mass finishing for tool machining, as well as producers of abrasives - trust in the optical measuring technology of Alicona."

Alicona measurement solutions for quality assurance in research and production are based on the areal measurement technique of Focus-Variation. "Focus-Variation is particularly used in tool and moldmaking for repeatable and traceable measurements of complex geometries with highly reflective properties, small radii and steep flanks," said the spokesperson. "Users achieve a vertical resolution of up to 10 nm."

Measurement of Cutting Edges after Deburring, Grinding and Polishing

Otec Precision Finish, with its headquarters in Germany, is a global technology provider of mass finishing machines. "Relative movement between the workpiece and the grinding and polishing granulate removes ridges, resulting in precise edge rounding down to 1 um," said the spokesperson. "In sample processing, only a high-resolution measurement system is capable to demonstrate edges in this precision to customers. This is why Otec opted for an Alicona measurement solution."

"The radius measurement via fitting an ellipse allows us to precisely visualize and measure the edge geometry, which is defined by mass and drag finishing," said Soran Jota, Managing Director of Otec Precision Finish. "Before Alicona, we were only able to use the common radius-fit. Today, we can work with a technology that enables us to achieve a higher resolution and greater accuracy. This has considerably increased our area of application."

Otec also uses Alicona for test purposes, to verify the edge geometry of deburred, ground, smoothed, polished tools and workpieces. This includes stamped components, turned parts and milled workpieces. In process engineering, measurements with the Focus-Variation are used for process monitoring.

Quality Assurance of Abrasives

Research often tries to analyze how grain structure and grain size of abrasives correspond to machining results. The Society for Production Engineering and Development (GFE/Germany) is one of the leading institutions in this area. Heinz-Wolfgang Lahmann, GFE measurement expert, uses Alicona to characterize the surface of abrasives. "We measure size, form, distribution and distance between the grains on the grinding tool," he said. "Measurements indicate the machining quality of the tool and the wear resistance of the abrasive. Abrasives have, just like ground and polished tool edges, highly reflective surfaces."

"Despite these challenging surface conditions, operators such as Otec and GFE achieve high-resolution measurements as Alicona measurement solutions work with a special illumination technology," said the spokesperson. "Due to the use of a ring light with diffuse illumination, the numerical aperture - an otherwise restrictive factor - can be positively influenced, as the light direction now only plays a minor role."

Form and Roughness Measurement

Alicona is a global supplier of optical 3D measurement solutions for quality assurance in research and production. "Our key competence is the measurement of surface finish and form of even complex geometries," said the spokesperson. "Our measurement systems combine the functionality of micro coordinate measurement machines (CMM) with those of a surface roughness measurement device. For a user, this means the measurement of both form and roughness of components on an areal basis."

For more information contact:

Alicona Corporation

1261 Humbracht Circle, Suite G

Bartlett, IL 60103

630-372-9900

sales.us@alicona.com

www.alicona.com

Otec Precision Finish

www.otecusa.com

GFE

www.gfe.com/en/