G&L 8" HMC retrofitted with a FANUC 0i-MD by CNC Engineering, Inc.

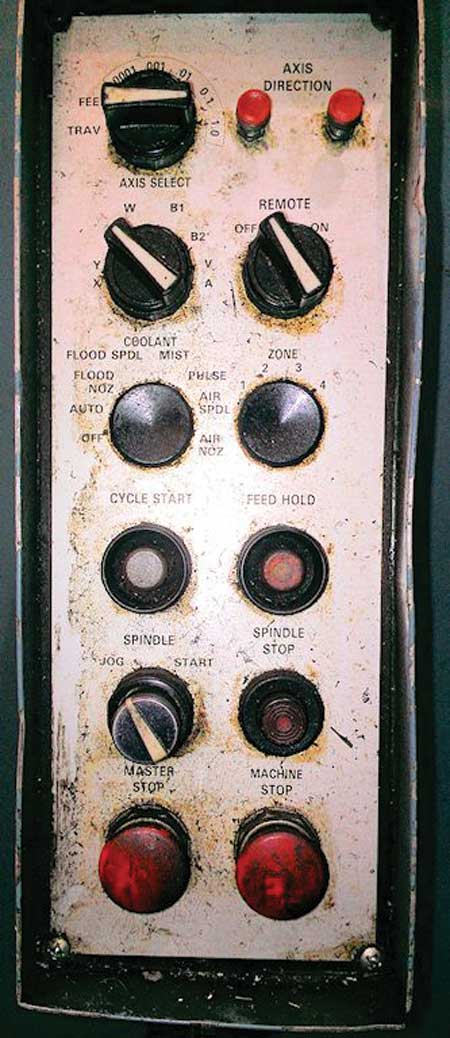

G&L hand-held pendant before retrofit

FANUC hand-held pendant after retrofit

"Giddings & Lewis (G&L) machine tools are prolific throughout North American manufacturing facilities and, for more than 50 years, many of the vertical turret lathes (VTLs) and machining centers built by G&L have served as reliable workhorses on their respective shop floors," said a CNC Engineering, Inc. spokesperson. "Many of these machines are now past their prime and, if left uncared for, will become more of a burden than an asset. However, there is hope.

"Upgrading to the latest CNC technology via a FANUC control retrofit and/or rebuilding mechanical systems on aging G&L machines is one way manufacturers can improve the accuracy, reliability and productivity of these machines, and at a much lower cost than buying new. Retrofitting and rebuilding will not only extend the productive life of these older machine tools, but will make them faster, smarter, easier to operate and will even lower energy costs in the process."

FANUC Retrofits

CNC Engineering, Inc. has retrofitted dozens of G&L machine tools throughout the country. "The most recent G&L machine tool retrofits feature FANUC 0i or 30i series controls, state-of-the-art servo motors with digital drives, redesigned operator pendants, new electrical enclosures and, if needed, new machine wiring," said Gary Caravella, President of CNC Engineering, Inc. "Compared to the old controls, the new FANUC controls are hundreds times faster, are available with a host of powerful functions and connectivity choices never dreamed of years ago."

A 5-axis G&L MC50 retrofitted by CNC Engineering, Inc. for a large contract manufacturer located in the Northeast involved rewiring the machine and replacing all valves and switches. Before CNC Engineering retrofitted the machine, operators were constantly reducing feedrates to alleviate chatter on large workpieces. The mechanics of the machine were in good shape but the vibration persisted and attempted calibration of the old servos also did not help. During the retrofit, CNC Engineering replaced the old system with new FANUC servos and successfully tuned the servos to completely eliminate the chatter, saving the company tens of thousands of dollars per year.

CNC Engineering also integrated a new high-pressure coolant system while maintaining the existing coolant systems. "Now, machine operators can select from flood coolant, low-pressure through spindle coolant or the new high-pressure through spindle coolant systems," Caravella said.

Machine operators were also managing a challenging build-up of chips under the old scales. CNC Engineering integrated new Fagor absolute linear scales with air purge and also added additional guarding to prevent any future chip build-up. The absolute linear scales are designed to eliminate the need for zero returning or homing of the axes.

The older G&L machines featured large hand-held operator pendants with limited functionality. These were replaced by smaller, more capable, user-friendly FANUC HMOPs during the control retrofit project.

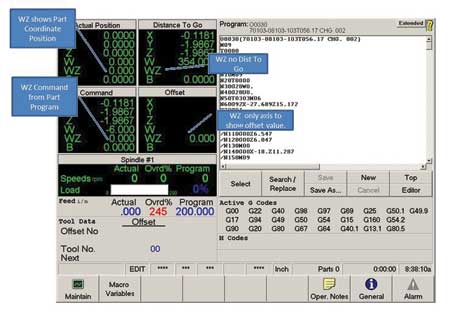

W/Z Tracking

CNC Engineering has taken its G&L retrofit packages one step further by adding a W/Z Tracking feature to its Open Vision HMI software. "While FANUC CNCs offer a standard W/Z Tracking option (parallel axis tracking), CNC Engineering's enhanced W/Z Tracking software is designed for ultimate operator friendliness, with features like displaying all relevant data on just one screen, thus eliminating the need to switch between multiple screens to use the option," Caravella said. Open Vision HMI includes a touchscreen interface that simplifies the operator interface, thereby increasing efficiency.

W/Z Tracking maintains the part coordinate relationship of a collinear set of axes, individually identified as the W-axis and the Z-axis. These two axes are collinear because each axis moves along a single straight line, which can be thought of as the W/Z-axis. The W/Z Part Coordinate System is established during set-up and represents the distance between the Z-axis part zero location and the W-axis part zero location along this W/Z-axis. The part reference point of the Z-axis is typically the gauge line of the spindle and the part reference point of the W-axis is typically a surface on the workpiece.

The W/Z virtual axis is shown on the main screen of CNC Engineering's Open Vision operator screens. These screens are set up to present to the operator the same information shown on a G&L machine with the older NumeriPath 8000 CNC. The W/Z tracking screens also display ACTUAL POSITION, COMMAND and OFFSET screens.

CNC Engineering, Inc. is a provider of FANUC CNC solutions for a variety of manufacturing industries. "As the largest FANUC CNC retrofitter in North America, we are committed to always exceeding customer expectations. We are very proud of our 98% customer retention rate," said Caravella.

For more information contact:

Gary Caravella, President

CNC Engineering, Inc.

19 Bacon Rd

Enfield, CT 06082

860-749-1780

www.cnc1.com