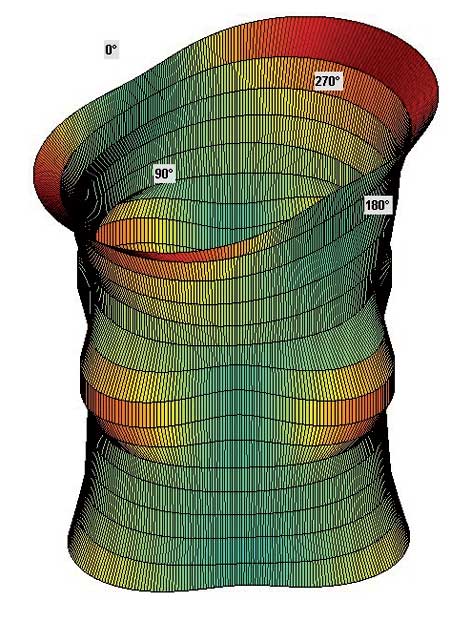

Out of round free form to compensate cylinder distortions

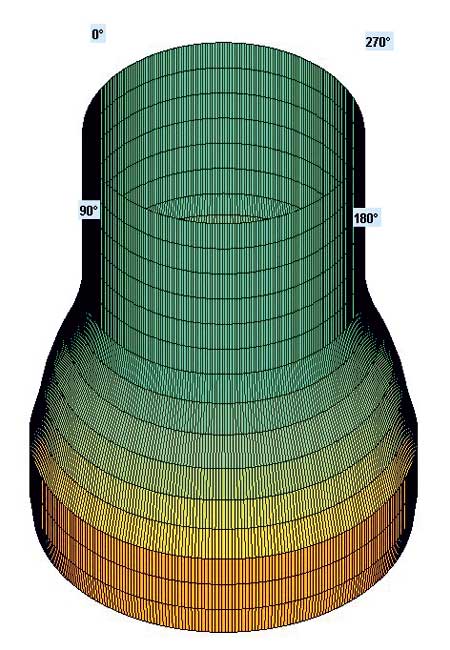

Rotation symmetric form to reduce friction at piston skirt (bottleneck shape)

Standard PT 600 honing machine equipped for form honing

"The use of form honing contributes to energy efficiency of modern combustion engines, especially in the reduction of CO2," said a Gehring spokesperson. "Until now, the production of combustion engines required cylindrical bores with high shape and surface quality. This machined macro form is not maintained for the function of the motor due to mechanical and thermal influences. During operation they cause complex distortion mechanisms that significantly deviate from the desired cylinder form. Therefore high ring tension is required to balance the cylinder bore distortions."

Gehring developed a form honing process that does not produce the cylindrical bore form as its goal, but instead achieves the expected cylindrical deformations, so that under specific operating conditions the quasi cylindrical bore geometries are achieved. This allows reduced piston ring tension, which results in reduced friction, improved fuel consumption and therefore a reduction of CO2 emissions. Furthermore, the current development of form honing considers the friction of the piston skirt of the cylinder's operating temperature, with specific clearance in the lower part of the bore. This is possible without impairment of the NVH behavior of the engine. During this process the friction between the piston skirt and the cylinder bore decreases.

Both innovative approaches - the freeform for the composition of cylindrical deformation and the local clearance for reduction of friction at the piston skirt - could be combined in a complex form or used separately. The benefits, in accordance with the high degree of freedom of the form honing, are the possible shapes, from the simple bottleneck form to the complex free form, which can be applied gradually.

Form honing is now a production mechanism that is highly developed. The components for the process are available. The local and temporary differences in the expansion of the individual honing stones are applied with mono or multi acting feeding systems. Conventional honing technology with honing stones of different lengths and stroke settings is not reliable for simple bottleneck forms. The Piezo encoder used for form honing works with the necessary dynamic precision and reliability. The friction optimized form honing tools are designed with durable abrasives. The final finish honing tools are engineered to help ensure consistent stock removal to achieve the required peak or plateau surface.

Advanced quality measurement concepts were defined in order to describe the complex free forms, which are also practical for mass production.

To monitor the process there are post process measuring equipment available, which stabilize the work results via feedback functions.

Form honing allows a high degree of free form tolerance close to a few micrometers to be achieved. Form honing can be integrated and automated into a standard single or multi spindle honing machine. Depending on the engine and the degree of form honing, the CO2 emission reduction is at least 3g/km.

Gehring Technologies GmbH offers several applications of this technology. Dr. Sebastian Schöning, CEO, sees diverse opportunities: "Gehring has started a new trend with form honing for the fine machining of bores in optimized lightweight components. Forming honing is a process development boost and broadens the application potential of honing. Form honing is an innovative contribution towards the future viability of the combustion engine, due to the achieved improved efficiency of the combustion chamber."

Authored by Dipl.-Ing. (FH) Gerhard Flores, Dr.-Ing. Andreas Wiens, Gehring Technologies GmbH

For more information contact:

Gehring L.P.

24800 Drake Road

Farmington Hills, MI 48335

248-427-3901

www.gehring.de