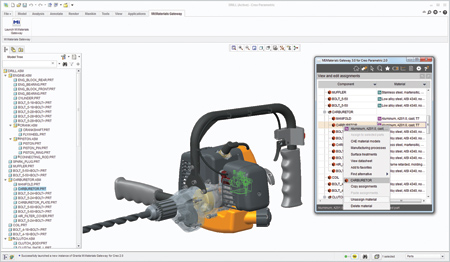

Editing materials assignments with MI:Materials Gateway 3.0 for Creo

Granta Design has released GRANTA MI:Materials Gateway 3.0, its third generation solution for accessing managed materials data within Computer-Aided Design (CAD), Computer-Aided Engineering (CAE) and Product Lifecycle Management (PLM) systems. Engineering enterprises manage wide-ranging and valuable information on the materials specified in their products (metals, composites, plastics and natural materials) using the GRANTA MI system.MI:Materials Gateway then provides this approved, traceable data directly within engineers' design, simulation or PLM environments, reducing time spent looking for information and ensuring accuracy and consistency.

Developed via partnerships with the CAD, CAE, and PLM providers, MI:Materials Gateway offers completely integrated functionality, appearing as a pop-up window inside the host system - no need for file transfer and no copy and paste. MI:Materials Gateway 3.0 takes full advantage of the functionality of GRANTA MI Version 8, and supports the latest versions of host systems, including Abaqus 6.14, HyperMesh 13 and Windchill 10.

Optimizing usability has been a key focus for this new release. Familiar operations such as copy, paste, undo and redo now operate directly on material and manufacturing process assignments in CAD. The ability for users to save and re-use combinations of search criteria that reflect their requirements further extends the concept of materials "favorites." Keyboard shortcuts provide a familiar application feel. "Together these ease-of-use enhancements provide quick, intuitive operation of Granta's material intelligence' functionality, within the host system," said a company spokesperson.

Interoperability has been further extended, with direct support for MI:Product Intelligence, Granta's solution for product risk reporting. Reports on risks associated with critical materials, restricted substances and more can now be run directly within CAD or PLM. This enables any product risk to be highlighted earlier in the design phase. In addition, materials assignment information can now be exchanged with MI:BoM Analyzer, Granta's new web app for assessing product risk from a Bill of Materials (BoM). For PLM users, there is increased flexibility in defining the PLM object types to which materials information and links are assigned.

"At Granta we are continually striving to offer our customers tools that provide real benefits within their engineering environments," said Dr. Arthur Fairfull, Product Director at Granta Design. "MI:Materials Gateway 3.0 reinforces our philosophy of creating integrated tools that help enterprises streamline their materials data management - providing a fast, flexible and easy-to-use tool for accessing materials information exactly where and when it is required."

For more information contact:

Granta Design

ASM International

9639 Kinsman Road

Materials Park, OH 44073-0002

800-241-1546

www.grantadesign.com