NUMConnect is fully compliant with the latest 1.3.0 version of the MTConnect standard and is available ready fitted or as a retrofit for all of NUM's Axium, Flexium and Flexium+ CNC systems, as well as its earlier generation Power 1000 series.

NUMConnect is available for all of NUM's CNC systems.

NUM has developed a new communications interface option for its CNC systems that fully complies with the open MTConnect interoperability standard. Known as NUMConnect, the interface can be fitted to new or existing systems and simplifies the integration of CNC machine tools with third party manufacturing management software. It is designed to enable users to implement powerful productivity-enhancing real-time data collection and retrieval facilities for production monitoring and analysis purposes.

"NUMConnect allows CNC machine tool builders to add further value to their products very easily and cost-effectively by providing uncompromised connectivity for manufacturing data," said a company spokesperson. "Manufacturers are increasingly making use of data retrieved from CNC machine tools on the shop floor to improve the efficiency of their production processes. However, until recently, the lack of a vendor-neutral data communications standard within the industry meant that CNC machine tool companies could only provide their customers with proprietary solutions for collecting and retrieving manufacturing data.

"To compound the problem, most CNC systems have a closed architecture and only provide a data link via their PLC, limiting data collection to the PLC's scan rate. The inflexibility of this approach - which also demands custom client software for each machine type - drove an industry initiative to bring Internet style connectivity to manufacturing equipment."

MTConnect, an open, royalty-free communication standard that can be used by anyone, is rapidly becoming the preferred choice of the machine tool industry. The standard is managed by the MTConnect Institute, a not-for-profit organization that seeks to improve the use of real data in manufacturing industries. A growing number of machine tool manufacturers are adopting the standard, which is also now supported by many leading suppliers of enterprise resource planning (ERP), manufacturing operations management and production dashboard software. "NUM was one of the first CNC manufacturers to offer an MTConnect compliant interface for an entire product range that does not require the use of third-party or custom adapters," said the spokesperson. The company originally introduced the interface on its Axium product line in 2008 and is now making it available as an option across its entire range of CNC systems.

The underlying technology of the MTConnect standard is the same as that used by the World Wide Web. It is based on Extensible Markup Language (XML) for capturing data that is readable by both humans and machines, with the format of all data transfers defined by hypertext transfer protocol (HTTP). NUM's open architecture CNC systems already use similar software technology for their human-machine interface (HMI), which is based on HTML and JavaScript and employs standardized server functions to facilitate the exchange of data between the CNC kernel, PLC, drives and motors. As a consequence, NUMConnect can read anything that is capable of being displayed on the CNC system's HMI, regardless of whether it is in analog or digital format. Even detailed low level machine data, such as motor, drive or encoder error messages, can be retrieved and used for monitoring machine performance, preventative maintenance or diagnostics.

Developed by NUM Corporation in the U.S., NUMConnect is fully compliant with the latest 1.3.0 version of the MTConnect standard and is available ready fitted or as a retrofit option for all of the company's Axium, Flexium and Flexium+ CNC systems, as well as its earlier generation Power 1000 series. The software can be installed on any standard PC equipped with Windows XP or later, and it runs in the background on any NUM industrial PC panel. "As a member of the MTConnect Technical Advisory Group (MTCTAG), NUM Corporation is committed to keeping NUMConnect up-to-date with the latest developments in the standard and to helping machine builders best exploit its benefits," said the spokesperson.

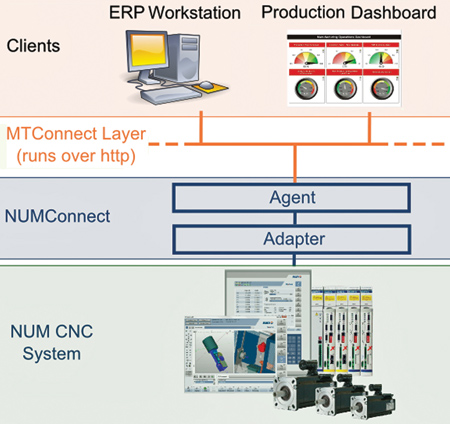

The NUMConnect software interface essentially comprises two main components: an MTConnect adapter and an MTConnect compliant information provider or lightweight Web server known as an agent. The adapter collects data from the CNC system, associates it with defined MTConnect data items, filters out any duplicates and then pushes the data to the agent, where it is held in a buffer store until overwritten by fresh information. To help minimize response times, MTConnect does not require the establishment of a formal data transfer session, and under normal use there are no log-on or log-off sequences. When the agent receives a request for information from any client application software, it transfers the appropriate data over the network using HTTP. The system is inherently secure; MTConnect is a read-only standard designed to facilitate the retrieval of data from manufacturing equipment - it does not control or instruct a CNC machine tool to take action.

"NUM's CNC systems feature open architecture hardware and software that provide machine builders with unlimited customization opportunities and simplify machine integration," said the spokesperson. "These same attributes also make the systems a popular platform for educational purposes NUM's products are used by several leading universities to familiarize engineering students with CNC technology and advanced machining techniques."

As Steven Schilling, General Manager of NUM Corporation U.S., pointed out, "Our policy is to use open, industry standard interfaces wherever practicable and the new NUMConnect interface option is a case in point. We believe that MTConnect compliant communications will become widespread, to the point where the technology will be regarded as the Bluetooth of manufacturing.' NUMConnect will help our customers, who tend to be small to medium sized OEMs, to compete with some of the larger players in the market by producing CNC machine tools that are ready for the trend towards even smarter manufacturing."

For more information contact:

Steve Schilling

NUM Corporation

603 East Diehl Road, Suite 115

Naperville, IL 60563

630-505-7722

sales.us@num.com

www.num.com