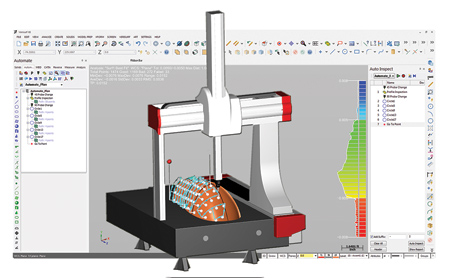

Verisurf with AUTOMATE has an intuitive user interface that includes a virtual view of the measuring device and real-time display of the inspection routine in progress. Color graphics illustrate inspection points relative to user defined tolerances: green = within acceptable tolerance, red = out of tolerance high, blue = out of tolerance low.

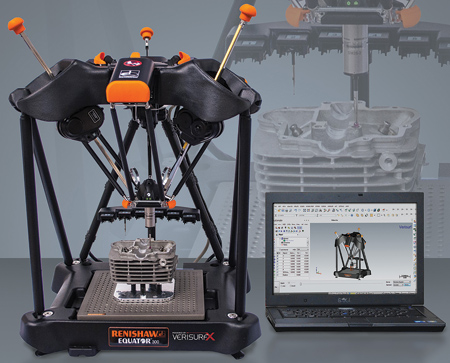

Driven by Verisurf with AUTOMATE, the Verisurf CMM Master is a fully functional programmable and portable CMM. Capable for use in the QA lab or the shop floor, the CMM Master can run both automated and manual inspection routines.

The Verisurf Master3DGage being used for in-process inspection. The part remains clamped in place on the CNC machine.

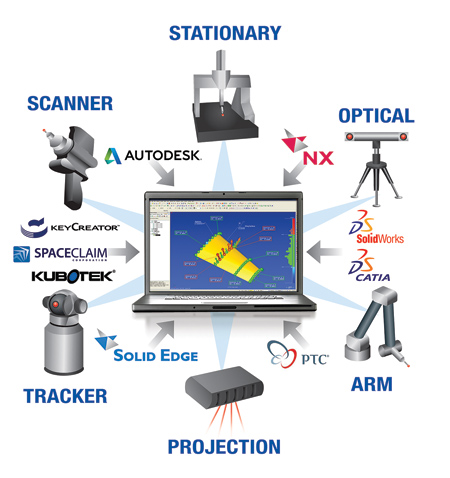

"Verisurf is committed to open communications and interoperability between all software and devices within the manufacturing digital workflow environment," said a company spokesperson.

Shop floor and in-process inspection have proven to be extremely beneficial for many manufacturing processes. Often, parts can be inspected right on the CNC machine without having to move them to the QA lab. This increases shop safety, especially with large parts, and avoids having the machine sit idle for long periods of time.

"In-process inspection by no means eliminates the role of the QA lab and stationery CMMs," said a Verisurf spokesperson. "Inspection of high volume production runs using automated routines and other specialized processes are best suited for the QA lab environment.

"The biggest challenge facing shops utilizing a combination of shop floor and QA lab inspection strategies is the need for a common software platform. In most instances there is a different software application for each device CMM, portable CMM, laser tracker, etc. The net result is increased training, support and maintenance across the board."

Verisurf Software with AUTOMATE provides a cross-enterprise solution based on a common platform approach. The company reported the following benefits of this approach:

- One interface to generate inspection reports in all popular formats

- One software interface and function controls to drive all digital measuring devices - stationery or portable

- One inspection software platform to streamline training, support and maintenance

- One software that supports automated and manual inspection routines.

Verisurf with AUTOMATE, a CAD-based inspection software, is designed to help CAD, geometric dimensioning and tolerancing (GD&T) datums and measuring devices work together to ensure design intent and help manufacturers move towards a model-based definition (MBD) environment.

Verisurf provides a common software platform designed to work with all CAD data formats, all portable measuring devices and all stationery CMMs committed to the I++ DME open communications protocol. "This commitment to open interoperability is the key to providing manufacturing enterprise measurement solutions," said the spokesperson.

Faster Inspections and Better Results

"The longer an inspection takes, the more opportunity there is for vibration, temperature change, compensation drift and numerous other environmental factors to degrade result accuracy," continued the spokesperson. "AUTOMATE eliminates calculation time, minimizes overall measurement time and provides immediate notification of out-of-tolerance conditions. AUTOMATE yields increased accuracy by reducing the time required to inspect a part, thereby mitigating the changing environmental factors that can degrade accuracy."

Manual and automated CMM inspection plans created in AUTOMATE are compatible with all brands and models of portable CMM arms, scanners, laser trackers, optical trackers and programmable stationary CMMs. In fact, the same measurement plan used to run a programmable CMM can be used with a portable arm.

"Whether the measurement job is on the shop floor or in the QA lab, this high level of interoperability empowers the technician to choose the ideal measurement device for the job," said the spokesperson. "Verisurf AUTOMATE improves measurement repeatability and reproducibility by ensuring that inspectors throughout an organization follow the same alignment, inspection and reporting process regardless of what hardware they are using. AUTOMATE can even create CMM inspection plans to STL files and automate the inspection of 3-D printed prototypes and additive manufactured parts."

For more information contact:

Verisurf Software, Inc.

4907 E. Landon Dr.

Anaheim, CA 92807

888-713-7201 / 714-970-1683

info@verisurf.com

www.verisurf.com