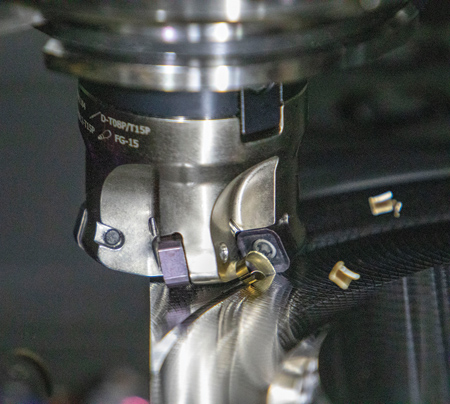

The Pramet double-sided SNGX11 inserts and SSN11 cutter expand the company's milling assortment.

The Dormer Pramet milling assortment for die and mold has grown with several introductions, including the double-sided Pramet SNGX11 insert for high feed milling with up to 0.07" depth of cut.

"A strong main cutting edge provides a high level of durability and process security-especially when machining corners inside a pocket," said a company spokesperson. "With eight cutting edges, the square-shaped SNGX11 also represents an economical solution."

Suitable for copy milling, helical interpolation, ramping, progressive plunging and face milling, the SNGX11 is available in two geometries. M is for machining steel as well as hardened steel and cast iron. MM provides a smoother cut and is more suitable for stainless steel, soft steel and super alloys.

The range is supplemented by the SSN11 cutter, which available in diameters from 1.26" to 4.92" with intermediate sizes for die and mold applications. All cutters feature a through-coolant design to further improve process security and a high overhang to support deep milling up to 10xD.

There are also additions to the Pramet ADMX07 milling program including an F geometry for finishing and semi-finishing applications. This sits alongside the existing M, FA and HF geometries and targets light machining of stainless steel and low carbon steels.

Suited to vibration sensitive machining, the chip breaker features a highly positive geometry with narrow peripheral land. This reduces chatter and enables a smooth cutting action without burrs on the machined wall.

"It also supports lower cutting forces, which not only reduces energy consumption, but also prevents work hardening, meaning increased durability and longer tool life," said the spokesperson.

For more information contact:

Dormer Pramet

2511 Technology Drive

Suite #113/#114

Elgin, IL 60124

847-783-5700

cs@dormerpramet.com

www.dormerpramet.com