"Offering no-mistake adjustments and accuracy to within 2 microns, Kennametal's eBore digital device is an optional-though extremely useful-part of the Kennametal Digital Boring System," said a company spokesperson.

eBore Universal: one head, multiple configurations, large diameter and boring depth range. The eBore digital display allows precision adjustment on the spindle, reducing set-up and idle time.

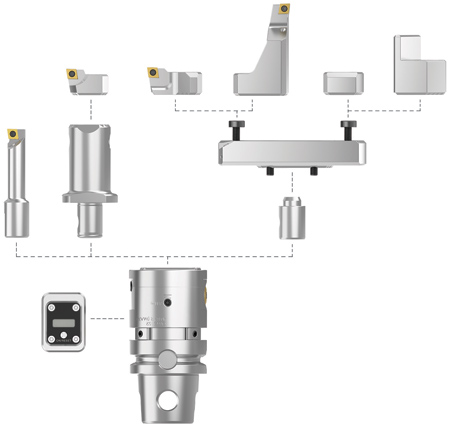

eBore Tool types (l-r) eBore Universal, eBore Fine Boring, eBore Bridge Tool, eBore Twin Cutter

Kennametal has introduced a line of digital-ready fine boring tools designed to make precision adjustment easy and enable more productive, predictable and accurate boring. The eBore Fine Boring System consists of cutting units to cover a diameter range from 6 mm to 1,020 mm (0.236" to 40.157") and an optional digital display that makes precision adjustments as simple as turning a screw.

"For many workpieces, the boring operation is often the final step, and a simple mistake can lead to scrapped parts. The Kennametal eBore fine boring system does away with the traditional `count the graduations' approach to boring and reduces costly mistakes," said Global Product Manager Marcus Paul. "We have found there is tremendous operator acceptance due to its simplicity and ease-of-use. And because the same eBore digital device can be used across multiple types of tools and on various machines, it is easy on the tooling budget as well."

"With Kennametal's digital eBore digital device, dialing in a tight bore and losing count of how far the adjustment screw was turned is a thing of the past," said the spokesperson. With an adjustment accuracy of 0.002 mm (0.00008"), the chip and coolant-resistant device contains a glass scale that keeps track of boring bar movement. Snap it in place, turn the boring head's adjustment screw by the desired amount and the tool is ready for the next boring operation.

With eBore, there is no need to remove the boring head from the spindle for adjustment or to count graduations or take notes. "Concerns over backlash and movement due to overtightening of the boring head's locking screw are a thing of the past, as are endless test cuts and `sneaking up on the bore,'" said the spokesperson. "The result is less scrap, less downtime and faster set-ups. The device shuts off automatically after 30 seconds and provides more than 5,000 adjustments between battery changes. And if you forget to remove the boring head before turning on the spindle, a ball and spring clamping mechanism releases the display automatically at 500 RPM, preventing potential injuries."

The eBore product line consists of four types of tools, all of which feature through the tool coolant, covering the following diameter range:

- eBore Universal Tool: 6 mm to 152 mm (0.236" to 5.984")

- eBore Fine Boring Tool: 20 mm to 205 mm (0.787" to 8.071")

- eBore Bridge Finishing Tool: 200 mm to 1,020 mm (7.874" to 40.157")

- eBore Twin Cutter Roughing Tool: 19.5 mm 1,020 mm (7.677" to 40.157").

The eBore system comes with Kennametal's KM quick-change interface and can be easily adapted to HSK, PSC, KM4X and steep taper spindles.

For more information contact:

Kennametal Inc.

600 Grant Street

Suite 5100

Pittsburgh, PA 15219

800-446-7738

www.kennametal.com