New High Performance Grade for Milling Nickel-Based Alloys

June 1, 2018

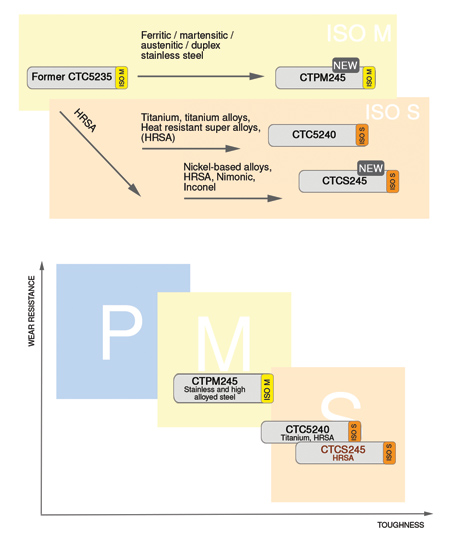

Comparison of CTCS245 to other CERATIZIT grades

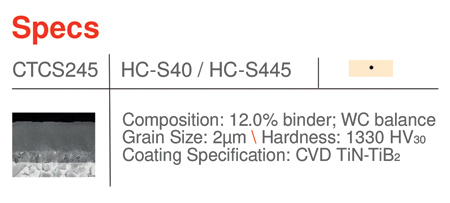

Specs of CTCS245

Cutting Solutions by CERATIZIT has introduced a new carbide grade into the ISO S family, CTCS245. This new CTCS245 grade is especially developed for milling applications in nickel-based alloys and heat resistant super alloys (HRSA) such as Nimonic, Rene and Inconel.

"Nickel-based alloys are notoriously difficult to machine," said Robert Bokram, Product Manager, CERATIZIT USA. "However, with our grade CTCS245, we are able to provide significant improvements in tool life and productivity, compared to similar competitive offerings, including our existing benchmark grades."

"The R&D team from Cutting Solutions by CERATIZIT is constantly working to develop tools that enable customers to produce parts more efficiently and more productively," said a company spokesperson. CTCS245 was designed with its aerospace customers in mind.

Its patented CVD coating contains titanium diboride, which creates a heat resistant, hard protective layer that resists edge build-up and mitigates the transfer of heat into the carbide substrate. This coating technology is optimized for machining these challenging aerospace materials.

The majority of CERATIZIT's standard milling products are now available in the new grade CTCS245.

For more information contact:

CERATIZIT USA, Inc.

11355 Stephens Road

Warren, MI 48089-1833

800-783-2280 / 586-759-2280

www.ceratizit.com

< back