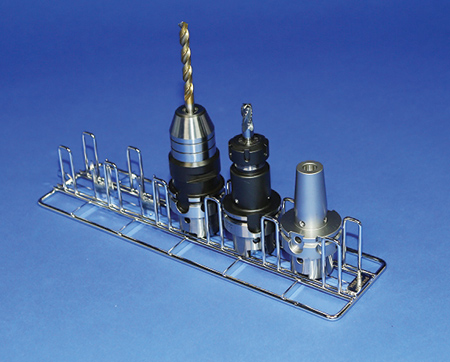

The inserts are adapted to different toolholders, e.g. HSK (as shown), Conus, VDI and SBA.

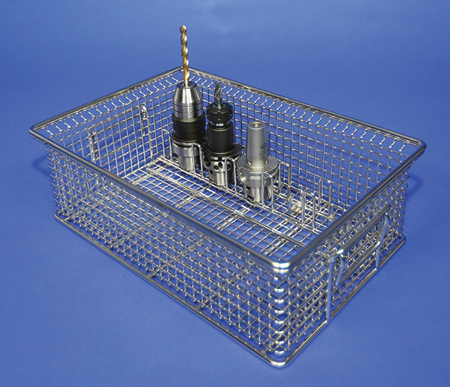

For cleaning, the inserts get fixed in a MEFO-BOX or standard cleaning basket. According to the dimensions of the working chamber of the cleaning machine, various and even different inserts can be placed in a basket.

Whether it is drilling, milling or turning, residues from the machining process are not only left on the part surface, but also in the tools and fixtures. Cleaning of the latter is usually still done manually, even though cleaning of the manufactured parts is carried out in a cleaning machine.

Metallform has developed specific inserts for standard cleaning baskets such as the MEFO-BOX. The inserts are available for different tool fixtures, e.g. HSK, Conus, VDI and SBA, and can be adapted to the type and size of the holders. Fixation of the holder in the insert only takes place at uncritical areas. They enable the fast, process reliable and economical automated cleaning as well as transport of the assembled toolholder.

Adapted to the size of the working chamber of the cleaning machine, the equipped tool fixtures can be placed vertically or horizontally - e.g. for deep-hole drills - in the insert. This also allows for placing the toolholder directly at the machine or machining center into the insert and for transporting it safely to the cleaning machine. Various and even different inserts can be placed in a MEFO-BOX or standard cleaning basket. The open design of the inserts allows the cleaning medium and mechanics, e.g. ultrasonic waves or spray jet, to reach the toolholders freely from all sides. In order to improve the cleaning effect, the basket can be swiveled in the machine.

After cleaning and replacing tools, the holders can be transported back to the metalcutting machine safely and without damages.

The inserts are made of stainless steel with an electrolytic polished surface. This material can be used with all cleaning media and ensures a long service life. The outer structure's rods are butt welded to avoid corners posing the risk of injury.

For more information contact:

Metallform

www.metallform.de