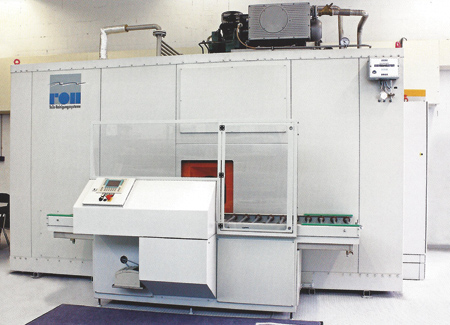

Single chamber flooding facility for halogenated hydrocarbons.

Karl Roll GmbH & Co. offers a variety of industrial parts cleaning solutions.

Multichamber immersion facilities are designed for high throughput applications, large batch weights, complicated part geometries and complex multilevel processes. The configuration as well as the accessory range are tailored to customer requirements.

Single chamber flood cleaning facilities, designed to be an all-around solution for most applications, feature compact exterior dimensions and optional features, such as ultrasound, pressure bath circulation and hot air and/or vacuum drying.

Pass-through spray cleaning facilities are principally intended for inline parts cleaning as part of the manufacturing process. From simple designs to intermediate cleaning and extending to complex multistage final cleaning systems, the systems can be matched to individual requirements.

Rotary transfer cleaning facilities, employing a spray and/or immersion process, are suitable for integrating into manufacturing lines for the cleaning of individual parts. They feature low space needs and short cycle times.

In the field of solvent cleaning technology, single chamber flooding systems for non-chlorinated hydrocarbon cleaning agents and modified alcohol are available. The facilities are operated under vacuum, so cleaning can be effected with the respective medium above its flashpoint. This means that optimum cleaning and drying results can be achieved and technical safety requirements fulfilled.

Alternatively, single chamber flooding systems for chlorinated hydrocarbons with integrated process air treatment can be operated without exhaust air.

For more information contact:

JCOM

8765 Guion Rd., Suite G

Indianapolis, IN 46268

317-343-4555

sales@jcom-import.com

www.jcom-import.com