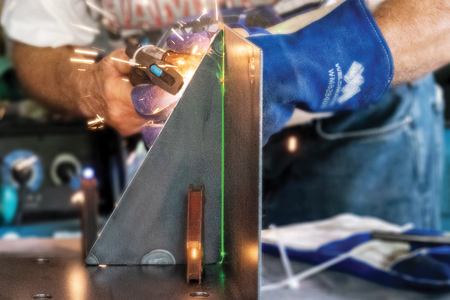

FARO TracerSI laser projector: 3D laser projector with advanced laser imaging for guided assembly and in-process verification.

"The TracerSI is an accurate and repeatable laser-guided assembly system with best-in-class projection accuracy and range," said a company spokesperson.

The FARO TracerSI fully supports feature-based alignment to shorten and simplify set-up time.

"A dust-sealed industrial enclosure with active thermal management allows the TracerSI to be a rugged and reliable solution for use in harsh environments," said a company spokesperson.

FARO offers next generation of the Tracer platform for laser-guided assembly and verification, the TracerSI advanced laser projection system. "TracerSI is a fully integrated, optimized solution that includes both innovative, improved hardware built upon the successful TracerM product and the best-in-class BuildIT Projector software," said a company spokesperson.

"Like its predecessor, TracerM, TracerSI uses 3D CAD information to project 3D laser images onto a physical surface and provides a live, visually rich virtual template that assemblers can use to quickly position components with precision," continued the spokesperson. "This solution can deliver significant ROI as organizations no longer have to invest capital in physical templates. Additionally, real-time manufacturing errors are minimized and, as a result, costly scrap and rework costs are reduced. There are documented cases where rework and scrap savings alone have payback periods as short as 90 days."

TracerSI features projection and high-resolution image scanning capabilities throughout its entire projection volume. Since the laser scanning camera does not rely on lenses or conventional image capture, the depth of field is equal to the full projection range. There are no lighting limitations since it is laser illuminated, and there are no limitations on frame size and resolution.

Fast Set-up with Feature Alignment

TracerSI offers native support of feature based alignment. With feature based alignment, retroreflectors (special targets that reflect light back to the original source) do not have to be placed on or around the object or assembly. This reduces the time required for set-up. Next, to synchronize alignment, the system performs high resolution image scans of the part or assembly to match known features (holes, edges, etc.) to the CAD model.

Enhanced Efficiency with In-Process Verification

"TracerSI is the first laser projector that enables In-Process Verification, or IPV," said the spokesperson. IPV uses the advanced laser scanning camera in conjunction with BuildIT projector software to perform quality checks. Throughout the assembly process, at any point, users can quickly run an image-based quality check and take any corrective or preventive actions to facilitate the end to end assembly process. This includes the ability to detect presence or absence of features during the assembly process or at final assembly. Additionally, at any point, loose fragments can be detected and cared for with the Foreign Object Debris (FOD) feature.

For more information contact:

FARO Technologies

250 Technology Park

Lake Mary, FL 32746

800-736-0234 / 407-333-9911

www.faro.com/laser-projector