Ohio Lt. Gov. Jon Husted initiates robotic ribbon cutting at Ohio State's Artificially Intelligent Manufacturing Systems Lab.

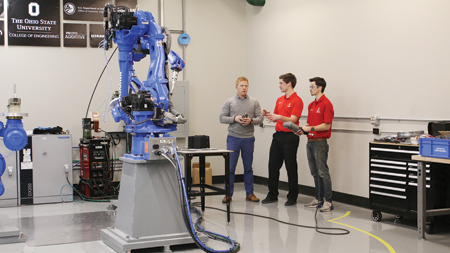

Associate Professor Michael Groeber works with undergraduate students Josh Coffey and Michael McCarthy in the Artificially Intelligent Manufacturing Systems Lab.

CDME Lead Engineer Walter Hansen demonstrates how to control a Yaskawa robot arm housed in the Artificially Intelligent Manufacturing Systems Lab. The lab is a first-of-its-kind test site for industry and academia to study and develop manufacturing systems that work with, and are controlled by, different types of artificial intelligence.

The Ohio State University is addressing the gap between industry and academia, and preparing for the next industrial revolution, by launching the first-of-its-kind Artificially Intelligent Manufacturing Systems Lab (AIMS) at The Ohio State's Center for Design and Manufacturing Excellence (CDME).

"The fourth Industrial Revolution-or Industry 4.0-is here, but most American businesses and schools are not prepared for how artificial intelligence (AI) will impact what they do. But The Ohio State is," said a spokesperson. "To prepare students for high-demand positions as the industry continues to adapt, The Ohio State recently launched a new degree: Bachelor of Science in Engineering Technology, with a concentration in manufacturing. This program combines broad training in manufacturing engineering technology with real-life, business-focused training. "As a recent Brookings Study showed, failure to capitalize on AI in manufacturing would cede a competitive advantage to our top global competitors and negatively impact the U.S. economy well into the next century," added the spokesperson.

Developed with input from industry, national defense and energy laboratories and university experts, the 1,500 sq. ft. AIMS lab space features three Yaskawa robot arms that stretch from floor to ceiling. Drawing from its innovative manufacturing ecosystem in the Columbus, OH, region, the lab supports AI manufacturing initiatives by:

- Teaching the next generation of students the right way, the first time. "The International Data Corporation (IDC) predicts that by 2025, 75% of organizations will invest in retraining and upskilling employees in order to fill skill gaps caused by AI," said the spokesperson.

- Bridging the gap between school theory and real-world applications. "Three out of five manufacturing companies are currently re-evaluating their AI implementation processes because of ongoing challenges with scope, budget and data management," said the spokesperson.

- Highlighting the business advantages of early adoption and scaling of AI in manufacturing. "According to the recent McKinsey & Company report, AI will potentially disrupt manufacturing supply chains, meaning management of this technology is paramount to meeting revenue and profit goals," said the spokesperson.

For more information contact:

The Ohio State University

281 W Lane Ave.

Columbus, OH 43210

614-292-OHIO

osu.edu