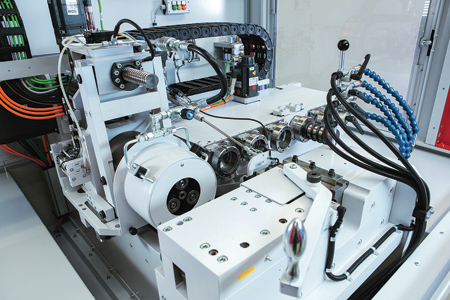

Mandrel bending machine DB 2060 CNC-SE

The t project software makes it possible to process isometrics directly from CAD.

In agriculture equipment manufacturing, the production has gone from manual manufacturing to industrial production. "What used to be processed for simple farm machinery is now at times highly automated and has to be done with planning," said a transfluid spokesperson. "This applies to all areas of agriculture, from tractors to combine harvesters and driverless machines for many different applications, and also to accessories like the small pieces of equipment used in agriculture."

Efficient Driving, Lifting and Motion

"When we look at tube processing for the manufacturing of agricultural machinery, we see two key types: heavy tubes and profiles that are often used in the construction of frames, and large hydraulics systems," said Stefanie Flaeper, Managing Director at transfluid.

Hydraulics is often the method used in agricultural machinery to drive, lift and move. transfluid offers a wide range of machines suitable for processing tubes for these applications, from a simple bending machine with mandrel-like the t bend DB 642K for mobile use and small numbers of tubes-to the highly flexible CNC-controlled systems with short set-up time and ability to bend clockwise and counterclockwise-like the t bend DB 630-CNC. "These machines provide very fast processes and higher output," said the spokesperson. "The drives of the tube processing machines are particularly high-performing and can be either hydraulic or electric with brushless motors, depending on the preference. All the challenges are met, whether working with small or large diameter tubes." Machines available for extreme geometries can bend both clockwise and counterclockwise in one operation. These generally have an electric brushless motor drive for large outputs.

Better Processes for Different Materials and Geometries

It is often the case that with hydraulics tubes there is a great variety of geometries and small numbers of production pieces. In this case, materials and geometries are particularly challenging. Although standard materials are used, other materials with significantly greater strength are used to meet the specifications. For this reason, the machines must offer the right level of flexibility. In this production area, it can make sense to have a manufacturing model that is based on one-piece flow or diverse when tubes of different diameters are needed for a product. The stock levels can be reduced and the tube is prepared completely before bending.

"Our goal is to greatly simplify and optimize the production processes with our solutions. To do this, our machines will produce tubes that are completely ready for immediate use after the bending," explained Flaeper.

The first step is the cutting, which is handled by the t cut range. The cleaning and automatic application of cutting rings and many different types of forming are also required. The forming and the cutting rings can be processed both ways in this case. The transfluid cleaning systems automatically deliver clean tubes. transfulid offers the complete processing of tubes and, if needed, the right automation systems with t motion for completely automated production.

Prototyping and Software for Safe Production

A key element for success in tube processing is prototyping. All transfluid machines can be operated manually to produce the first set of tubes. In addition, tools are available to measure the component, or even the whole set of components, in a flexible way and directly on the item to generate accurate digital data. The t project software makes it possible to process isometrics directly from CAD. Both the technical department and the machine operator can use a number of different interfaces to import data and run collision tests.

"With our advanced software, even the very first tube is ready to be used in a manufacturing process," said Flaeper. "This way, transfluid offers tubes to the manufacturers of agrotechnical products, which are ready to be incorporated and produced in a way that is extremely close to the final manufacturing standards."

For more information contact:

Yannick Bludau, Technical Support

and Sales North America

transfluid Maschinenbau GmbH

+49 151 / 12 69 88 17

ybludau@transfluid.de

www.transfluid.net