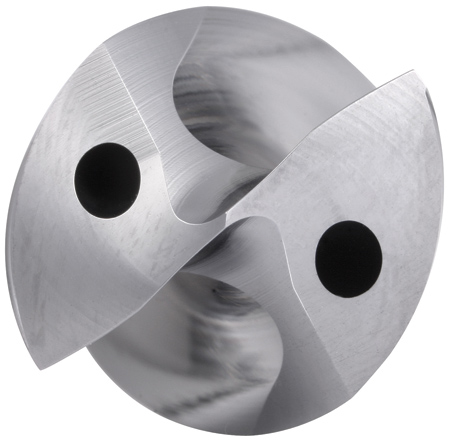

The B21*SGL gash geometry has a constantly increasing rake angle, which is engineered to provide smooth chip formation and reduced cutting forces, and an outer margin designed to prevent chipping.

"Scrapping an expensive part like an engine casing due to a broken tool is simply unacceptable. The B21*SGL solid carbide drill from Kennametal delivers high performance and ensures process safety," said a company spokesperson.

The B21*SGL solid carbide drill from Kennametal is available in a broad range of inch and metric sizes, hole depth up to 8xD.

Kennametal has introduced a high-performance cutting tool, the B21*SGL solid carbide drill with coolant-through. "Designed for stainless steel, nickel and cobalt-based alloys, the B21*SGL with patented point geometry and monolayer PVD AlTiN coating offers improved productivity and longer tool life for aerospace and energy applications requiring predictable, high-production drilling," said a company spokesperson.

"In customer tests, the B21*SGL consistently outperforms competing drills, producing more holes in less time with improved hole straightness and surface quality," said Frank Martin, Product Manager, Solid Carbide Drills. "The new design virtually eliminates the risk of chipping and flaking, which leads to drill failure. And due to a unique point gash, it offers the lowest thrust level on the market, enabling productive drilling even in delicate workpiece geometries."

According to Kennametal, one of the problems with these materials is their tendency to stick to the cutting tool, leading to built-up edge and corner chipping. "The B21*SGL's proprietary gash geometry, polished cutting edge, negative rake corner margin and chip-friendly flute design mitigate these effects while encouraging chip evacuation and reducing cutting forces," said the spokesperson. "Add to that Kennametal's wear-resistant, high aluminum content KCMS15 grade and you have a drill that not only makes more holes per tool, but does so more quickly and predictably."

"A number of our customers have seen tool life improve by two to six times in a variety of challenging materials, even after increasing feedrates by up to 50% in some cases," said Martin.

Holemaking is a critical machining process, especially so for those producing turbines. Because the drilling operation typically comes near the end of the production cycle, when workpieces are at maximum value, a broken drill can damage or even destroy components worth tens of thousands of dollars.

"This new solid carbide drill will bring incredible value to anyone needing to drill large numbers of holes in Inconel, titanium, PH-series stainless steels and other heat-resistant superalloys. It is especially relevant to aerospace manufacturers, given the tremendous pressure to ramp up production of the LEAP aircraft engine program," said Matthieu Guillon, Key Account Manager, Aerospace.

For more information contact:

Kennametal Inc.

600 Grant Street

Suite 5100

Pittsburgh, PA 15219

800-446-7738

www.kennametal.com