The fully automated SW dual-spindle machining center BA 321 produces two completely machined forcep halves every three minutes.

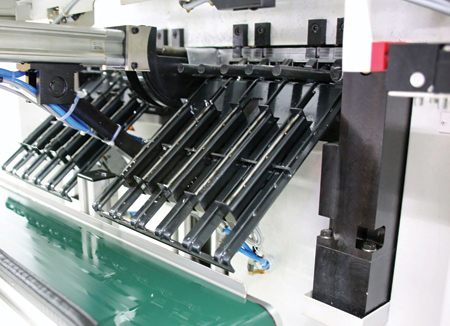

An elaborate drawer mechanism ensures controlled deposit on a conveyor belt.

Surgical instruments are high-precision products that are manufactured with great care, usually in small quantities. The structures and equipment of manufacturers specializing in these products are therefore designed above all for a high level of flexibility in retooling. "A separate process chain should accordingly be set up for one-time products in large quantities. The key element is a two-spindle machine from Schwäbische Werkzeugmaschinen GmbH (SW) with high repeat accuracy," said a company spokesperson.

"The requirements are high and the competition is hard in manufacturing of precision mechanical surgical instruments," said Frank Pauschert, Regional Sales Manager of SW in Germany. His customers include a company in this sector that has grown from modest beginnings when it was founded in the 1980s to become a mid-sized enterprise with about 130 employees. Currently about 1,000 different instruments are manufactured for a wide range of surgical applications. All instruments come complete and ready for use. The individual parts are made of premium biocompatible materials, such as stainless steel, and are manufactured in machining processes. Despite the use of modern NC-controlled machine tools, manual operations make up a great deal of the manufacturing process for these instruments because they consist of up to 40 different components that must be refined, surface-treated and meticulously assembled by hand. In addition, they are often manufactured with numerous variants. This necessitates small batch sizes and because of that, a prime requirement of the relevant manufacturing systems is very flexible retooling. Due to the extraordinary diversity of variants, there is also no way to work from stock and lower costs by manufacturing in larger batches.

"Since the manufacturer has not previously produced any of its own products, it is constantly compared with the numerous competitor products already available in terms of price by customers, who often have great market power," said the spokesperson. "This limits profitability and with it, future growth possibilities." To safeguard the future in the long-term, a decision was made about how to enter an extremely challenging large-scale production project: manufacturing of a one-time tool for neurosurgery that is used so often that hundreds of thousands of units are needed annually. It is a type of forceps made of aluminum that can be used to grasp tissue components while stopping minor bleeding with electrical pulses. Minute tubes were also integrated into each arm of the forceps through which an irrigation fluid can be directed into the operating area. Despite its straightforward appearance, the instrument requires very time-consuming manufacturing with numerous mechanical and manual work cycles, all of which must meet strict quality requirements. Many of these work cycles have to be carried out under a microscope. Setting up the process chain requires extensive development efforts as well as investments in machines and special equipment. Additional employees have to be hired and qualified for this purpose.

The starting point and key element of the process chain is an automated dual-spindle BA 321 machining center from SW. The system has a working area of 300 mm x 500 mm x 375 mm per spindle. The spindles are equipped with an HSK A63 interface and reach speeds of up to 17,500 RPM with a chip-to-chip time of 2.5 s. The tool change system has a capacity of from 2 x 20 to maximum 2 x 60 slots. This system is used to mill forceps halves made of aluminum. It has a custom-made automation unit for supplying material and removing milled parts. It is only intended for a limited range of parts, but within that range achieves more productivity than any other milling centers in the plant. With its horizontal, dual-spindle design, the new machining center delivers two completely milled forceps halves in just three minutes. Due to the automation system, it can do this around the clock, largely without supervision. The machine also features high repeat accuracy and thus quality of manufactured parts. In addition, it surpasses the throughput performance of the other machining centers installed on site.

"We chose SW first of all because we were impressed by the productivity of the double spindle concept," said the customer. "Another aspect was their impeccable references as well as the relative proximity, which would mean short response and travel times both during the joint development phase to come and also for any service calls that might be needed."

The initial contacts led to a partnership-based collaboration during which the possibilities for automation of machining processes was clarified. This was followed by joint design and development of a special machine based on the model BA 321. Special press-drawn sections in three different dimensions are used as raw material. The forceps halves are carved out of the sections and are not separated by sawing until the last work cycle. This neatly sidesteps clamping problems with the extremely slender and delicate forceps halves from the outset. The final saw cut is made so that a minimal amount of burr remains to prevent the pieces from falling down. Otherwise the very delicate tips of the forceps could be damaged. The forceps are removed by special adapters loaded into the spindles from the tool magazine. They are used to hold the forceps parts and break off remaining burrs. Then they are deposited individually on a transport drawer and moved by conveyor belt to the removal station, where they are manually inserted in basket racks for the next work cycles.

During the joint development and project planning phase the necessary tools were implemented and an initial NC program was created based on customer requirements. After acceptance was completed, the system was placed in operation. Since then there have been tests as well as programming for a total of 18 product variants. The system sometimes runs for up to a week with no human interaction other than supplying material and removing finished milled parts.

Due to "life startUp" production monitoring in the first week after commissioning, the employees became familiar with operating the machine quickly and were able to work independently with it. With life data, an online service of SW, the machine is continually connected online to SW, where essential machine parameters are monitored non-stop. If problems come up, action is taken immediately and the machine operator is supported by remote diagnostics. When problems occasionally came up, it provided quick and very competent consulting, and if a service employee was needed at all, he was often on site for less than an hour. Without this service there is much that would not have worked, or would have taken much longer.

The BA 321 is the two-spindle version of a series that is available as a one-, two- or four-spindle machining center depending on the task. It is suitable for machining workpieces made of aluminum, cast iron, titanium or steel. The heart of the monobloc is the working area with dimensions of 300 mm x 500 mm x 375 mm and the spindles which are movable in 3 axes. The spindles with HSK-A63 interface reach speeds up to 17,500 RPM with an output of 32 kW (4,200 RPM, 40% duty cycle) and a torque of 72 Nm. The spindle distance is 300 mm. The weight of the system is about 8,500 kg, while the standard installation dimensions are 3.60 m x 3.13 m x 6.00 m (W x H x D). The series 3 is available as a single-station machine or with a double swivel carrier.

The feed of the 3-axis unit is provided by sturdy ball screw drives, with rapid traverse axis reaching speeds of 65/75/75 m/min (XYZ direction) and axis acceleration rates of 10, 10 and 15 m/s2 respectively with a maximum feed force of 8,000 N. The pick-up tool changing system has a capacity from 2x20 to max. 2x60 tools in the two-spindle variant. Tools up to O 70 mm (160 mm with free adjacent slot) with a maximum length of 275 mm and a maximum weight of 7.5 kg can be picked up. The chip-to-chip time is about 2.5 s. The Sinumerik 840 D sl, Bosch Rexroth IndraMotion MTX or FANUC 30i are available as a control unit.

For more information contact:

SW North America

30160 Lyon Industrial Ct.

New Hudson, MI 48165

248-617-3800

contact.na@sw-machines.com

www.sw-machines.com