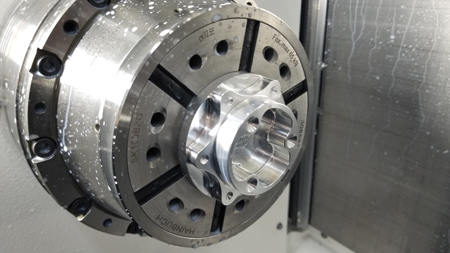

Component for steering wheel adaptor machined with Hainbuch workholding at VAC Motorsports.

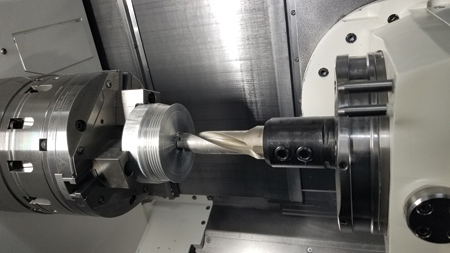

Aluminum Multi V (Serpentine) Pulley machined using Hainbuch workholding and B-axis drilling.

In the days before the automobile became a computer-based mechanism requiring highly customized software and special tooling, an iconic group of enthusiasts devoted much of their spare time to do-it-yourself repairs and upgrades. Affectionately known as "shade tree mechanics," they used the most basic tools and typically worked out of their garages and driveways, or, in more crowded urban neighborhoods, on the street. One such individual is Tony Salloum, a Lebanese American who began his automotive career in front of his parents' home in Philadelphia, PA.

Salloum's mechanical talent and ingenuity led to the formation of Verna's Auto Clinic (V.A.C.) in 1984-a three-man shop involved primarily in body work and restoration. By 1987, V.A.C. became involved with BMW Automotive specialties and repairs and ultimately entered the racing scene. After local successes, the group entered the difficult world of Middle East Rally racing and in 1996 won the FIA F2 Group A championship. In 1997, the firm expanded with the acquisition of Milano Engine & Machine, a dedicated builder of racing engines that was established in 1963.

Today, VAC Motorsports operates a body shop, full-service repair shop, full engine and manufacturing machine shop, and an extensive retail new and used parts facility. Specializing in BMWs, VAC Motorsports continually engineers improved performance parts, which are developed with the latest in CAD/CAM software and produced in a fully equipped manufacturing facility.

According to Salloum, "Although many Americans are not as familiar with BMW's racing credentials as with other makes, the BMW is a good, reliable and affordable race car-especially the 3 Series. In the USA, races are sanctioned by BMW CCA Club Racing, SCCA, NASA (National Auto Sport Association), IMSA, World Challenge and other organizations, and can also be found around the world. In fact, BMW racing is extremely popular in Australia."

Although VAC Motorsports maintains an inventory in excess of 2,000 parts, production runs tend to be low volume due to the specialized nature of the units. The need for workholding capability that combines high precision and quick changeover led Salloum and his team to the Hainbuch precision workholding system.

"We are always on the lookout for tools that can improve our performance and shorten our changeover time between parts, and we learned about Hainbuch from magazine ads and ultimately IMTS," said Salloum. "Our production equipment includes an Okuma mill-turn lathe with live tooling and a sub-spindle. We also have a Mazak i-100S Bartac that can accommodate a 4-foot bar. Most of what we work with includes 6061 and 7075 aluminum and various steel grades including 4140 heat-treated. The Bartac machine accommodates 72 tools and has been fitted with a Hainbuch SPANNTOP 100 mm system. For example, if we are making parts roughly 1 inch long, we can load a 48-inch bar and it will operate unattended, producing the parts quickly, with precision and perfection."

"Another example involves a more complex two-part steering wheel adaptor designed for quick release," continued Salloum. "These are more complex parts, and we typically make them in runs of 50 pieces. With our Hainbuch system, the changeover time between parts can be as low as 5 minutes, which significantly improves our production capability. The repeatability of 2 microns assures the precision we require."

Brian Eaton, Northeast Regional Sales Manager for Hainbuch America Corp., noted, "VAC Motorsports maintains an inventory of collets ranging from 5/8 inch to 1-1/8 inches in 1/8 inch increments and from 1-1/4 inches to 4 inch capacity in 1/4 inch increments. While there is an excellent inventory of Hainbuch standard components available, we can also supply them with specialized designs should the need arise."

Salloum said, "In our business, flexibility is everything since we have to be able to deliver both the simplest parts, such as spacers and O-rings, and the more complex ones. For example, we have just introduced an S54 Billet Aluminum Block in both wet and dry variants for high horsepower turbo applications and racing applications, and an E90/E92/E93 M3 Billet Differential Cover for use by both street cars and racers. Components such as these are what sets us apart as an extremely valuable resource for our customers."

At present, much of the automotive coverage in the popular press is given to the advent of electric vehicles and driverless cars. "While such vehicles will unquestionably serve utilitarian purposes, as long as there are those who thrill to the quest for increased speed, and whose aesthetic sense can appreciate a beautifully designed and manufactured component as a work of art, VAC Motorsports will continue to set new standards," said Salloum.

For more information contact:

HAINBUCH America

W129 N10980 Washington Dr.

Germantown, WI 53022

800-281-5734 / 414-358-9550

sales@hainbuchamerica.com

www.hainbuchamerica.com

VAC Motorsports

www.vacmotorsports.com