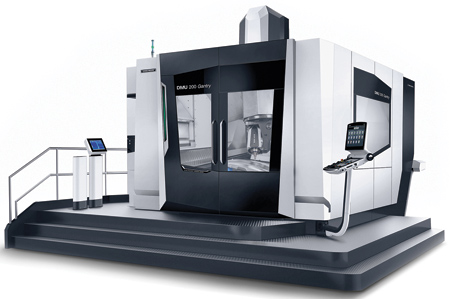

The DMU 200 Gantry enables dynamic machining of large components at up to 50 m/min rapid traverse.

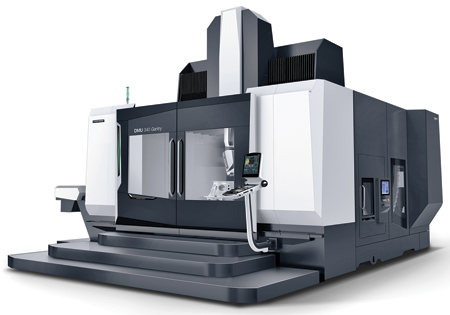

The cubic work area of the DMU 340 Gantry provides a clamping area of 2,700 mm x 4,400 mm.

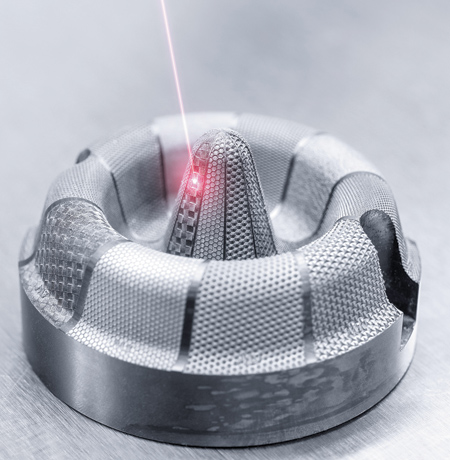

The surface structuring with the aid of the LASERTEC Shape provides unlimited design freedom.

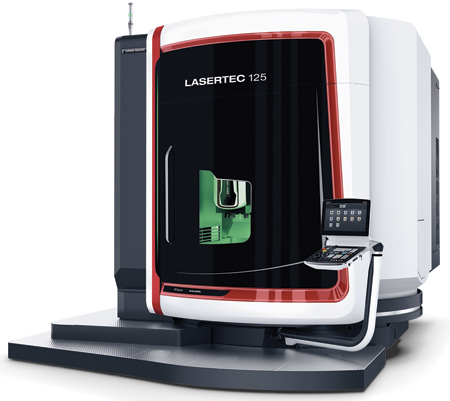

LASERTEC 125 Shape provides 3D laser texturing of free-form surfaces in workpieces up to 2,600 kg.

Swage hip nail machined on the DMC 650 V

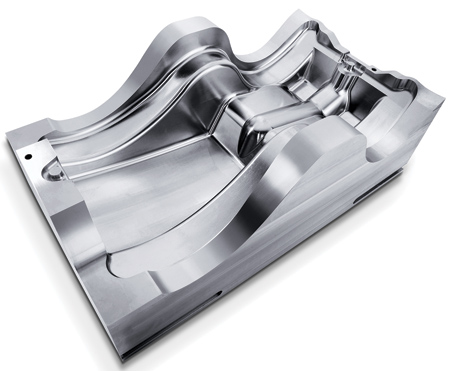

Bobbycar mold machine on the DMU 65 mB

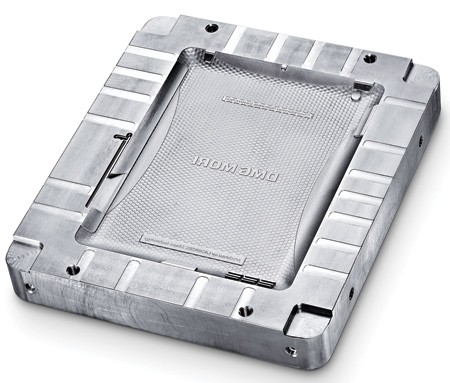

Injection mold for tablet PC cover machined on the LASERTEC 75 Shape is made from aluminum and measures 290 mm x 220 mm x 65 mm.

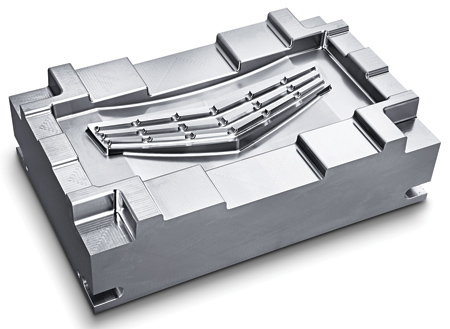

Radiator grill mold machined on the NVX 5100. The workpiece is SKD61 steel and measures 700 mm x 450 mm x 150 mm

DMG MORI's 50 years of experience in tool and moldmaking have resulted in enhanced technology solutions. At its s in Pfronten and Iga (Germany), local experts design individual manufacturing solutions with integral process chain specifically for the small batch sizes that are common in tool and moldmaking.

Complex components, high demands on precision and the required productivity are crucial factors that determine tool and moldmaking across all industries-from packaging and medical engineering to automotive engineering. At the same time, experts at the DMG MORI are faced with the challenge to realize economical manufacturing solutions for ever-new applications. Close cooperation with customers starts during very early project phases, from the first draft up to implementation of the process including programming, automation, process monitoring and quality control.

Optimum Manufacturing Technology for Every Application

The heart of the manufacturing solutions are machine tools from DMG MORI. The wide portfolio of machining centers and turning machines provides a comprehensive range in this area for the DMG MORI . While the portal and gantry series is successfully used in the production of large components, the DMU 60 eVo linear, the DMU 85 monoBLOCK and the DMU 90 P duoBLOCK are used in tool components and moldmaking. Additionally, the LASERTEC Shape series provides economical surface structuring of the molds, while the additive machines LASERTEC 30 SLM 2nd Generation and LASERTEC 65 3D hybrid can combine materials of different thermal conductivity or hardness, thus optimizing cycle times or resistance to wear.

The comprehensive process orientation, standardization methods and automation solutions-for example with regard to pallet handling with the driverless PH-AGV 50 (Automated Guided Vehicle)-result in an improved competitive edge for customers. Combined with the high performance of the DMG MORI products, DMG MORI reported that customers can often achieve up to 6,500 spindle hours per year, depending on the machine.

LASERTEC 125 Shape

Highlights of the LASERTEC 125 Shape:

- Large components with a diameter of up to 1,250 mm x 700 mm and 2,600 kg, < 19 sq. m installation area (without platform)

- State-of-the-art 100 W fiber laser with switchable pulse length and frequency of 10 - 1,000 kHz

- New Fast Scan Mode for machining at up to 4 m/s

- New high-speed Z-shifter (optional) for machining 3D surfaces at up to 4 m/s (theor. 30 m/s)

- Long-term accuracy due to monoBLOCK design and smartSCALE measuring systems from MAGNESCALE with resolution of 0.005 µm in the linear axes

- Unlimited possibilities in the design of individual structures.

For more information contact:

DMG MORI - Americas Headquarters

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

Service Hotline:

855-DMG-MORI (364-6674)

us.dmgmori.com