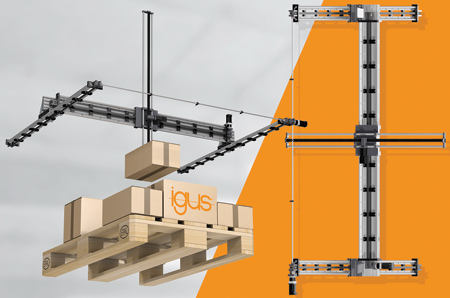

The self-lubricating and maintenance-free drylin XXL room linear robot from igus lifts up to 10 kg.

The XXL Large DIY 3-axis linear gantry robot from igus has an action radius of 2,000 mm x 2,000 mm x 1,500 mm and is particularly suitable for palletizing applications of up to 10 kg. The system is easy to set up and program using the do-it-yourself principle without the help of a system integrator.

The DIY kit enables companies to quickly install a pick & place 3-axis linear gantry for tasks related to palletizing, sorting, labelling and quality inspection.

Alexander Mühlens, Head of the Low-Cost Automation Business Unit at igus, said, "We have developed a solution that is many times more cost-effective due to the use of high-performance plastics and lightweight materials, such as aluminum. It is a low-risk investment that usually pays off within a few weeks."

The buyer receives the 3-axis linear gantry as a DIY kit. It consists of two toothed belt axes and a toothed rack cantilever axis with stepper motors and an action range of 2,000 mm x 2,000 mm x 1,500 mm. A maximum length of up to 6,000 mm x 6,000 mm x 1,500 mm is also possible.

The package also includes a control system, cables as well as the free igus Robot Control (iRC) software. Users can assemble the components into a ready-to-use system in just a few hours without external help, prior knowledge or lengthy training. If additional components such as camera systems or grippers are needed, users can find them on the robotics marketplace RBTX.

As an example, a cartesian robot can be used on conveyor belts that transport products away from injection molding machines. The robot picks parts with a maximum weight of 10 kg from the conveyor belt, transports them at a speed of up to 500 mm/s and positions them on a pallet with a repeatability of 0.8 mm. This automation relieves employees of physically demanding and time-consuming palletizing work, freeing up resources for more important tasks.

The system also requires no maintenance. The system's linear axes consist of corrosion-free aluminum, and the carriages move via plain bearings made of high-performance iglide plastics. The self-lubricating properties of the igus bearings enable a low-friction, dry operation without external lubricants.

The iRC software from igus enables simple and intuitive robot programming and control, allowing for an easy entry into automation. The free software allows users to program different robot kinematics.

"For many companies that do not have in-house IT specialists, programming robots is often fraught with problems," Mühlens said. "That is why we developed iRC, a free software application that visually resembles commonly used office software and allows intuitive programming of movements. What makes it special is that the software is free, and the resulting low-code programming can then be used 1:1 on the real robot."

The core of the software is a 3D digital twin of the 3-axis linear gantry, which can be used to define movements with a few clicks.

Mühlens added, "Prospective buyers can use the 3D model to check whether desired movements are actually feasible before making a purchase. Furthermore, we invite all interested parties to try out our robots live or via the Internet free of charge. We support them during commissioning and show what is possible with low-cost robots. It makes the investment virtually risk-free."

For more information contact:

igus, Inc.

P.O. Box 14349

East Providence, RI 02914

800-521-2747

sales@igus.com

www.igus.com