Measuring Technology for eMobility

March 1, 2024

Roughness sensor provides uninterrupted measurement.

Precise detection of micro-structures using a probe sphere and probe needle.

Gearboxes for electric vehicles require a particularly high level of manufacturing accuracy for the gears that are used. The waviness and roughness of gear surfaces are important parameters in this. To meet this need, Liebherr-Verzahntechnik GmbH has further developed its WGT measuring instruments and fitted them with the relevant features.

Liebherr's WGT series of gear inspection machines have already been in use in sectors including gear manufacturing in vehicle construction, in the aviation sector and in general engineering. Every model fulfils the strict specifications of VDI/VDE 2612/2613, Group 1 and measures gears upwards from a 0.1 mm module. Lapped granite guides help ensure the thermal profile is uniform. Linear axes with air bearings, precision rotary tables and Renishaw probe systems with tactile probes help ensure the machine is mechanically accurate. Automatic correction of adjustment data is based on LHInspect, the user-friendly gear measurement software.

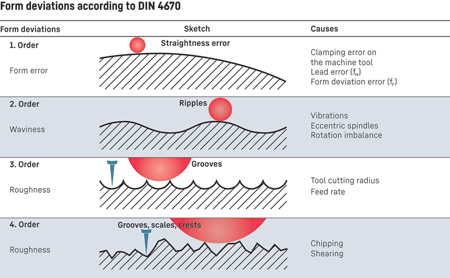

In eMobility, quality requirements for gear surfaces are particularly high. Especially important is accurately measuring roughness and waviness. A roughness value that is as low as possible is an important parameter in power transmission and smooth running of gearboxes. Waviness plays an essential role in controlling noise emissions and is vitally important for almost silent electric motors. Measuring waviness exactly is a must in manufacturing gears for e-gearboxes.

Liebherr-Verzahntechnik GmbH further developed the WGT sensor system and the LHInspect software especially for these requirements. A new roughness sensor registers the microstructure of the gear surface even more precisely. The software analyses roughness as well as waviness and the waviness values can even be evaluated retrospectively without additional effort. Liebherr is one of only a few providers globally to offer these extensive functions.

The roughness sensor has been further optimized to detect an even smaller boundary point. An automatic stylus change rack enables uninterrupted measurement of the workpieces in one step. This means the measurement is not just precise, but also efficient and user-friendly. The WGT offers a high reproductive accuracy up to 1.2 µ and, with the environmental temperature appropriately monitored, can reach greater precision value.

For more information contact:

Liebherr Gear Technology, Inc.

1465 Woodland Drive

Saline, MI 48176-1259

734-429-7225

info.lgt@liebherr.com

www.liebherr.com

< back