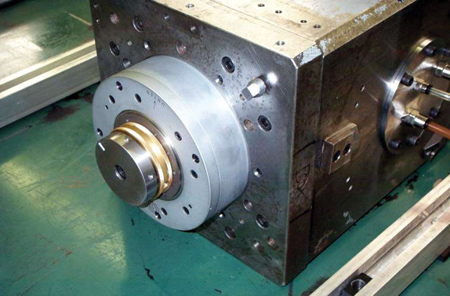

Spindle head (front). The new flanged cartridge spindle mounted in the existing SNK spindle head assembly.

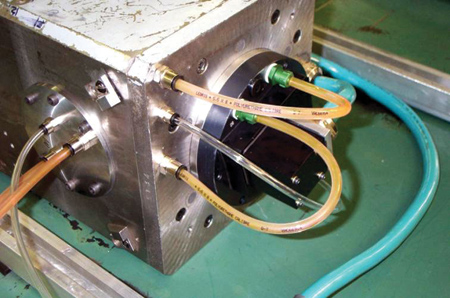

Spindle head (rear). The new flanged cartridge spindle mounted in the existing SNK spindle head assembly.

The success of retrofitting a machine with an enhanced spindle design system can be measured by the overall benefits and the longevity these benefits bring to the machining process and, ultimately, how it positively affects a company's production environment.

"Increased production potential, improved machining capabilities, ease of operation and reduced downtime are benefits realized by a Centerline customer on a spindle system retrofit of an SNK 5-axis dual spindle machining gantry," said a Centerline spokesperson.

The original spindles on this SNK gantry were 20,000 maximum RPM integral motorized spindle assemblies consisting of three-piece spindle cast housings. The machining applications called for RPMs in the 12,000 to 15,000 range. The main housing contained the stator assembly with the front and rear end caps containing the spindle bearing journals. The spindle had liquid cooling, utilized oil lubrication for the spindle bearings and incorporated cutting fluid ports through the spindle mounting block. The spindles had automatic tool change capabilities, but were the tools were normally changed by hand per customer preference.

This customer had production requirements for this large gantry that required running the existing spindles at an RPM that put additional strains on the spindle power capabilities while making heavy machining cuts.

The challenge of this project to alleviate the problematic issues was twofold. It required staying within the space limitations of the existing spindle head assembly while allowing full 5-axis movement of the original machine design in order to prevent from limiting the machining capabilities of this SNK gantry. The retrofit called for a cylindrical flanged cartridge spindle assembly and a new spindle frequency drive installed for each spindle head on this machine.

The spindle used for this retrofit project was a custom 150 mm flanged cartridge unit, grease lubricated, water cooled and operating 5,000 to 15,000 RPM at high torque. The spindle tool change interface is a manual HSK 63 system.

The spindle frequency drives installed to run these spindles allowed maximum performance and ease of operation.

"Compared to the old spindle design, this new spindle system provided superior machining finish due primarily to the added rigidity of utilizing a self-contained spindle cartridge and the ultra-precision high accuracy and high rigidity spindle nose bearings," said the spokesperson. The new spindles further enhanced the machining capabilities of this SNK gantry by increasing the spindle motor horsepower to 12 (9 kW) with high torque capabilities.

The spokesperson concluded: "Enhanced performance and ease of operation without compromising machine capabilities is part of what made this project an effective solution. Increased production and reduced downtime were realized due to a dramatic increase in spindle life, making this retrofit a success for the end user."

For more information contact:

Centerline, Inc.

2110 N Ash

Ponca City, OK 74601

800 696 2865

info@centerline-inc.com

www.centerline-inc.com