DMG MORI additive manufacturing (AM) solutions include powder bed and powder nozzle methods.

With AM Consulting, the DMG MORI supports companies by providing expertise and by establishing process chains linked with the LASERTEC 3D, LASERTEC 3D hybrid and LASERTEC SLM series.

The rePLUG powder module enables material change in less than two hours.

OPTOMET software calculates the optimum process parameter automatically, makes programming easier and results in improved surface qualities and reproducible material properties.

DMG MORI develops integral processes linked with additive manufacturing (AM) on the LASERTEC 3D, LASERTEC 3D hybrid and LASERTEC SLM machines at its Additive Manufacturing Excellence Center in Chicago. Solutions include powder bed and powder nozzle methods, as well as conventional machining. The center features a modern measuring laboratory and a lab for metallurgical testing.

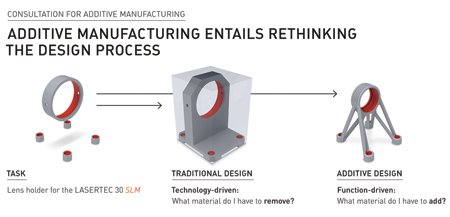

AM Consulting

With its new consulting approach, DMG MORI supports companies by providing expertise and by establishing process chains linked with the LASERTEC 3D, LASERTEC 3D hybrid and LASERTEC SLM series. The consultancy portfolio encompasses services along the entire process chain of AM, including the AM Quick Check as an introduction to realizing this potential.

AM and Machining from a Single Source

With its diversified machine portfolio in both machining and AM, DMG MORI approaches the topic holistically. If AM is to become established on the shop floor, it is essential to integrate this method into existing production systems and process chains-especially where successfully progressing from prototype and small series production to serial production is concerned.

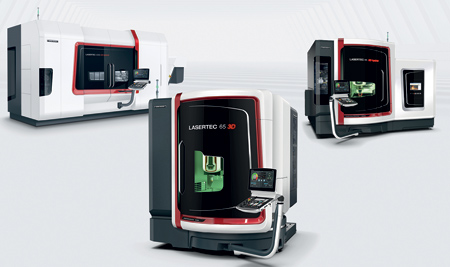

The most widely used in the DMG MORI series, the LASERTEC 65 3D hybrid, is suited for the additive manufacture of complex prototypes and small series parts and for the repair and coating of components. The LASERTEC 65 3D, which is geared solely towards laser deposition welding, is a complement to existing machining centers on the shop floor. The LASERTEC SLM series expands the portfolio to include the powder bed method using selective laser melting. With the combination of AM technologies and conventional CNC machines, DMG offers four individual needs-based process chains.

LASERTEC 3D Hybrid

The LASERTEC 3D hybrid and LASERTEC 3D machines provide laser deposition welding with a powder nozzle. The first combines AM and conventional machining in a single set-up. The LASERTEC 65 3D hybrid is designed for the 5-axis simultaneous machining of parts measuring up to o19.68" x 15.74". The LASERTEC 4300 3D hybrid enables 6-sided turn and mill operations for workpieces with sizes up to 25.98" x 59.05". Designed for complete machining of demanding geometries, the LASERTEC 3D hybrid machines enable flexible changeover between laser deposition welding using a powder nozzle and mill or turn operations.

LASERTEC 65 3D

A second process chain based on the powder nozzle includes the compact LASERTEC 65 3D for 5-axis laser deposition welding and a machining center for final finishing of the additively manufactured components. This makes the LASERTEC 65 3D a suitable addition to machines already installed on the shop floor, optimizing utilization of production capacity. With travel paths of 28.93" x 25.59" x 22.04", the work area of the LASERTEC 65 3D is around 40% larger than the hybrid version and its footprint is about 45% smaller.

LASERTEC SLM

The LASERTEC SLM series is designed for AM in the powder bed (selective laser melting). The LASERTEC 30 SLM 2nd Generation has a 11.81" x 11.81" x 11.81" build volume.

The new LASERTEC 12 SLM is designed to provide above average accuracy and features a focal diameter of 35 µm. This allows a finer resolution of the structures, enabling thinner wall thicknesses. Build volume is 4.92" x 4.92" x 7.87".

Both models are designed to provide flexibility, productivity and process security. One of the highlights is the rePLUG flexible powder module. It allows for changing of materials in less than two hours. The closed powder circuit is designed to provide a high degree of safety during work and process autonomy. Both machines feature an ergonomic design and offer better accessibility of important components.

Two process chains can be realized with powder bed technology. AM produced workpieces can be finished to the required surface quality on a milling machine, such as the 5-axis DMU 50 3rd Generation. Also, the LASERTEC SLM machines can finish previously milled base plates and bodies without any need for support structures.

The integral software solution for CAM programming and machine control CELOS completes the process chains with the LASERTEC SLM series. The coordinated and uniform user interface enables parts to be programmed externally with minimum time expenditure and transferred to the machine. Due to the efficient flow of information and intuitive operation, CELOS offers optimum processes in the pre- and post-processing of additively manufactured parts. In addition, the open system of the LASERTEC SLM series enables individual adjustment of all machine settings and process parameters, right through to include an unlimited choice of material manufacturers.

OPTOMET

With a share of 30% in software developer INTECH, DMG MORI has gained access to key software and technological expertise for generative production. INTECH specializes in AM and related software solutions, including artificial intelligence. A first result of this collaboration is the new OPTOMET software, which INTECH offers for the LASERTEC SLM series. It has self-adjusting and learning algorithms that calculate the required parameters of the SLM process in advance and within minutes. This means layer thicknesses, for example, can be calculated freely, which in turn enables a faster and more productive build. OPTOMET also has a material database that allows users to use material from all manufacturers without having to test them in advance.

The open system also allows independent expansion of the database using the customer's own experiments. OPTOMET is also able to adjust parameters in a way that material properties-such as hardness, porosity and elasticity-can be changed or optimized.

For more information contact:

DMG MORI - Americas Headquarters

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

Service Hotline:

855-DMG-MORI (364-6674)

www.us.dmgmori.com