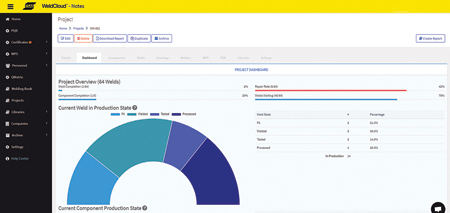

WeldCloud Notes monitors welding production bottlenecks and provides a full weld traceability dashboard that keeps track of every weld and component in a project.

ESAB Welding & Cutting Products has introduced WeldCloud Notes procedure qualification records (PQR) and welding procedure specifications (WPS) document management software as part of its ESAB Digital Solutions suite of online management tools.

WeldCloud Notes enables companies to better perform four essential tasks:

- Maintain quality and compliance while managing PQR and WPS documents in one place

- Efficiently review all of its PQR, WPS and weld procedure qualifications (WPQ) information with a quick and easy search feature

- Generate a PQR or WPQ with all essential variables

- Prevent missing a qualification expiration date or wasting time and money on requalifying welders.

WeldCloud Notes provides full compliance to construction codes (ASME VIII, ASME B31.3, EN 1090), welding standards (ASME IX, ISO 15614-1, ISO 9606, AWS D.11) and welding quality standards (EN 3834). It enables fabricators to track the productivity of individual welding systems and welders, register weld seam data and manage the calibration records for an entire fleet of welding machines.

"WeldCloud Notes helps companies increase productivity, reduce costs, avoid liabilities and improve quality assurance during project execution," said Ludvig Enlund, General Manager Digital Solutions, ESAB. "This online software tool enables every relevant person on a project to access information, search for the correct qualifications, create welding procedures, introduce welding records, keep track of production and print reports for all the activity completed."

ESAB created WeldCloud Notes when it acquired WeldNote, a Lisbon, Portugal-based welding software business founded by brothers Tiago Pereira, a welding engineer, and Pedro Pereira, a software engineer. Tiago is now an ESAB Product Manager focusing on WeldCloud Notes and Pedro is the lead software developer for WeldCloud Notes.

"Our vision was to reduce the burden of time-consuming administrative tasks and eliminate sources of human error," said Tiago Pereira. "We chose ESAB to acquire us because their vision with ESAB Digital Solutions perfectly aligned with ours."

Two Core Users Groups

"WeldCloud Notes especially appeals to QA/QC managers by enabling them to check production status in all shops, identify production bottlenecks, reduce repair rates by removing weak procedures and target underperforming welders for more training or reassignment," said the spokesperson. Welding engineers can use WeldCloud Notes to analyze and compare project requirements with their company's PQRs, WPS or welder qualifications. Engineers can search company records by base material or filler metals (and more). The PQR and WPQ generator software enables them to create procedures based on qualifications, introduce essential variables, calculate approval ranges and generate a PDF with all information.

"WeldCloud Notes provides managers and engineers with a multitude of functions that eliminate tedious manual tasks and sources of human error," said Pereira. "We continue to add new features, such as the ability to generate joint diagrams from scratch."

For more information contact:

ESAB Welding & Cutting Products

800-ESAB-123 / 864-466-0921

www.esabna.com