Crankshafts supported between centers

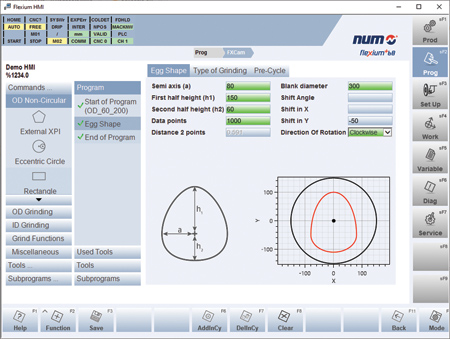

Section of the input page for the egg shape

"Software from NUM provides manufacturers of CNC cylindrical grinding machines with an elegant means of adding non-circular grinding capabilities to their products-without incurring significant development time and cost," said a company spokesperson. "Non-circular grinding is used in a wide variety of automated manufacturing applications, such as the production of camshafts, crankshafts, cams and eccentric shafts. However, it is an extremely complex task, because the non-circular contour leads to constantly changing engagement and movement conditions between the grinding wheel and the workpiece."

NUM has now added non-circular grinding functionality to its NUMgrind cylindrical grinding software, which forms an application-specific element of the company's Flexium+ CNC platform. It is fully compatible with other Flexium software, from release 4.1.20.00 onwards.

NUMgrind is specifically designed to simplify the creation of G-code programs for CNC grinding machines through the use of a highly intuitive graphical human machine interface (HMI), conversational-style fill-in-the-blank type dialogues or a combination of the two.

"Unlike conventional CAD/CAM workstation tools for generating CNC machine tool control programs, NUMgrind is intended for use in the production environment," said the spokesperson. "It enables shop floor personnel to handle everyday machining tasks quickly and efficiently-and the work can be easily shared among several people and several machines."

The NUMgrind HMI can also be run on an office PC. Application-dependent projects, and the corresponding ISO part programs, can be created, tested with NUM's Flexium 3D simulation software and transferred to the targeted machine.

The operator simply determines the sequence of the grinding process via the HMI and enters the necessary data for the grinding operations, grinding wheels and dressing operations in the dialogue pages. Programming is further simplified by the fact that the HMI is supported by a comprehensive library of predefined shapes, which includes eccentric circles, hexagons, pentagons, polygons, Reuleaux triangles and rhombi. The CNC program is then created completely automatically and stored in an executable form.

The closed shape of the workpiece is defined in the XY plane. However, grinding is performed by interpolating or synchronizing the X-axis with the C-axis (workpiece spindle). Axial movement in the Z-axis can also be accommodated by means of oscillation or multi-plunge. The Flexium+ CNC system's NCK transforms the contour from the XY plane into an XC plane, and calculates the corresponding compensation and in-feed movements, taking the grinding wheel diameter into account. The speed profile is also transformed, so that the speed and acceleration are automatically adapted to suit the physical attributes of the machine.

For more information contact:

Steve Schilling

NUM Corporation

603 East Diehl Road, Suite 115

Naperville, IL 60563

630-505-7722

sales.us@num.com

www.num.com