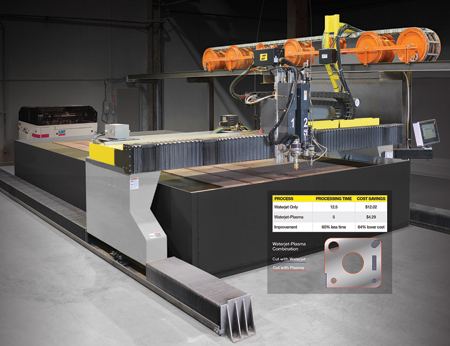

ESAB Hydrocut HDX large gantry cutting system combines the precision of waterjet technology with the speed of plasma cutting to lower part cost and cycle time by up to 60 percent or more.

Many parts lend themselves to cutting fine contours with waterjet, then cutting large contours with plasma to produce the part for a fraction of the cost of cutting the entire part with waterjet.

ESAB Welding & Cutting Products has introduced its new Hydrocut HDX large gantry waterjet cutting system for cutting over a work area measuring up to 18' wide x 56' long. The Hydrocut HDX can be equipped with up to four waterjet cutting heads, two oxy-fuel stations and up to two plasma stations, including ESAB's DMX Plasma Beveller. It can also be equipped with various marking tools for high-speed text or line marking, including plasma marking, pin stamping or inkjet plate marking.

"The Hydrocut HDX combines the precision of waterjet with the speed of plasma to optimize cycle time and quality," said Steve Zlotnicki, Global Product Manager, ESAB Cutting Systems. "Combining technologies can lower part cost by up to 60% or more, as well as increase productivity and enhance safety through reduced part handling."

"Waterjet technology provides high precision on contoured shapes, a smooth edge with no bevel, no heat-affected zone and no dross, creating perfectly finished parts that require no secondary cleanup or machining," said a company spokesperson. "It also cuts almost any material and can handle sheets up to 6 in. thick. However, it is a comparatively slow and expensive process. By combining waterjet with plasma on the same gantry, customers can produce more parts for lower cost when compared to typical waterjet-only systems."

"Large fabricators and steel service center operations benefit from the Hydrocut HDX's waterjet-plasma combination to better meet customer needs," said Zlotnicki. "Many parts lend themselves to cutting fine contours with waterjet and then cutting large contours with plasma. This lets you produce the part for a fraction of the cost of cutting the entire part with waterjet."

ESAB offers two waterjet intensifier pump options. For the fastest speeds and lowest cost per part, ESAB recommends the KMT Streamline PRO-III (90 KPSI) intensifier in either 60 HP or 125 HP pump options. For standard cutting, the KMT Streamline SL-VI intensifier (55 KPSI) or PLUS pump (60 KPSI) in either 30 HP, 50 HP or 100 HP is recommended.

The Hydrocut HDX is based on ESAB's Suprarex gantry with dual-linear rail Y-axis guiding system to deliver the high dynamic accuracy necessary to produce high-quality parts with high-cut precision. The gantry can reach a maximum speed of 1,000 IPM and is capable of cutting widths from 8' to 18' and lengths up to 56'. Both X and Y axes are protected with bellow covers to keep abrasive materials and moisture away from the rails.

"The Hydrocut gantry has a proven reputation for reliability and durability, as does the system's Vision T5 controller. They provide a solid foundation for fast, flexible and economical cutting," said Zlotnicki. The controller features a touchscreen interface, EasyShape part program generator, EasyNest option and built-in process database to enable users to quickly and easily set up new cutting routines.

For more information contact:

ESAB Welding & Cutting Products

256 Midway Drive

Union, SC 29379

800-ESAB-123 / 864-466-0921

www.esabna.com