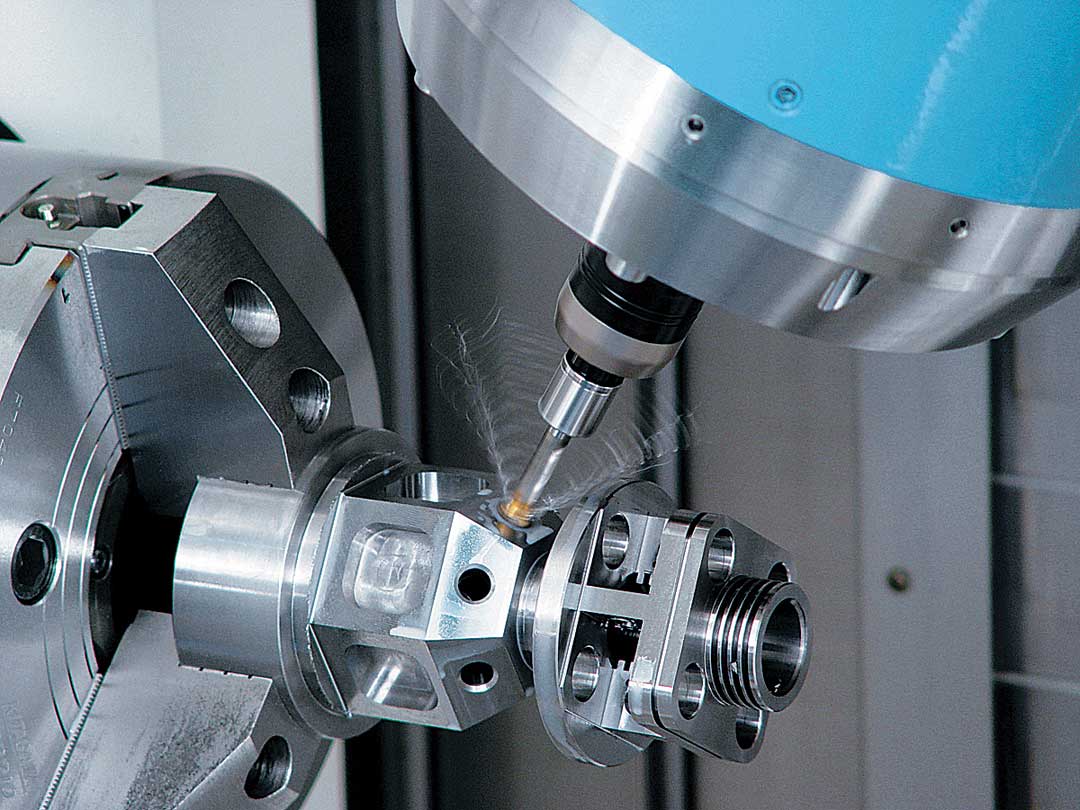

A BIG DAISHOWA sales team member demonstrates key features and benefits of tools.

Every BIG Collet is precision-made to AA Grade and inspected twice for accuracy. Each collet is verified for 100% concentricity, ensuring runout within .00004" at the nose.

The BIG DAISHOWA MEGA SYNCHRO Tapping Holder, which is designed to improve thread quality and extend tool life, reduces thrust loads from synchronization errors by up to 90%. Super-slim nuts and multiple tap holder lengths provide optimal access to tight spaces.

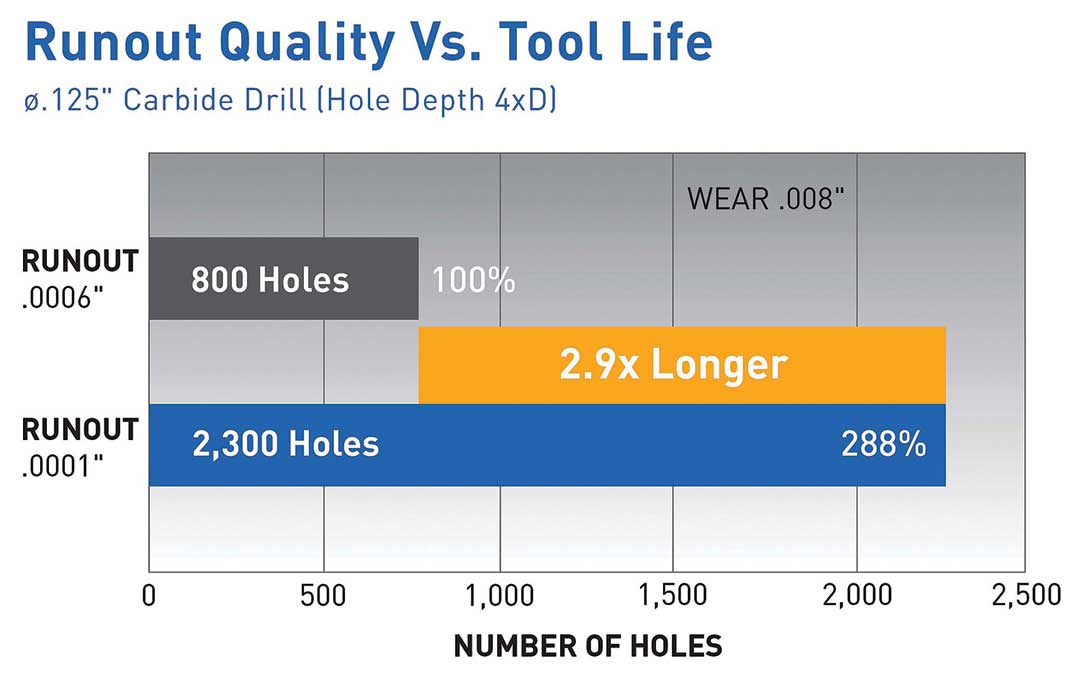

The carbide drill lasted 2.9x longer at the lower runout level and produced 288% more holes.

An integrated damping mechanism within the toolholder functions as a dynamic counter and friction damper, instantly absorbing vibrations and eliminating chatter. This results in higher machining accuracy, improved surface finishes, and increased metal removal rates for greater productivity at critical depths.

When it comes to keeping the books in the black and the spindles spinning, are your operations sustainable? You work to win new customers, deliver parts on time and in spec, and retain quality employees. But what about environmental sustainability efforts? They may play a bigger role in long-term business viability than you think, especially when it comes to tooling.

In fact, the quality of a toolholding system not only affects how environmentally friendly an operation is, but also how profitable.

Four Ways Better Toolholding Improves Sustainability

A scrapped part here. Prematurely worn inserts there. A new machine spindle several years before it should need replacement. It all adds up to more metal in landfills or scrapyards and less money in your pocket. And it is a sign that your toolholding choices could be costing you. Quality toolholders, on the other hand, can have a positive impact on your operation.

1: Reduced Material Waste

Poor toolholder performance directly leads to scrapped parts and rework-whether you notice it at first or not. When tool runout exceeds acceptable tolerances, parts fail quality inspections. It is not good from a sustainability standpoint, either. While some scrap gets recycled, much of it does not, ending up in landfills instead. But the environmental impact is only part of the story.

Particularly in high-stakes industries like aerospace, medical and heavy equipment, scrapped parts cost big money. You are paying three times: for the material itself, for the wasted time, and for the impact on customer satisfaction.

2: Reduced Consumables Waste

Even if the majority of your parts are passing inspection, you could be throwing money away on consumables that are wearing down prematurely because of subpar toolholders. The math is simple and proven: For every one-tenth (.0001") of runout added, tool life will decrease by 10%.

Take this real-world example:

- Drilling tests with eighth-inch diameter carbide drills showed that at 80 millionths (just under .0001") of total indicated runout, we drilled 150 holes before reaching the wear limit.

- When we double that runout (to .0002"), we see a 10-15% decrease in tool life.

- When we get up to .0006" runout, which many would consider acceptable runout, we have cut our tool life in half.

- That means if you are at an "average" runout, you could be spending twice as much as you need to on consumables.

Oftentimes, switching toolholders is the answer to reducing runout. For example, one BIG DAISHOWA customer switched to the Mega Synchro holders for tapping operations in 4140 steel and tool life jumped from 35 holes per tap to 2,500 holes.

And it is not just runout. Even minimal vibration can be a silent profit killer. That is where options like Smart Damper toolholding technology come in. It not only reduces vibration in challenging long-reach applications for better tool life and more reliable part quality, it also helps operators bump up speeds and feeds to improve cycle time. As any shop owner knows, time is money.

Tool life matters from an environmental standpoint, too. While carbide recycling programs have grown in recent years, it is likely that under half of all scrapped carbide is recycled. And even for those who recycle 100% of their used inserts, the significant energy and resources to recycle the metal takes a toll. Creating new inserts is equally taxing: The tungsten used in carbide tools is increasingly precious; 75% of tungsten originates in China and it takes one ton of earth to produce a single pound of it.

3: Less Equipment Waste

If you think toolholding choices cannot have catastrophic consequences, think again. In one scenario a shop invested in new, high-end machine tools, only to fill the 200-tool magazine with cheap toolholders. Within a year, the new machine spindle was damaged to the tune of $80,000.

That is because toolholders with poor accuracy or inadequate grip transmit excessive vibration and force irregularly into the spindle. So, it is not just the part you have to worry about-it is the wear on one of your machine's most important and expensive components.

Scrapped machine parts or whole machines themselves are harder to recycle, so the amount of waste can be significant. Not to mention the impact on your bottom line.

4: Lower Energy Usage

With all the benefits of quality toolholding mentioned above, machines can actually produce more with less energy. For U.S. energy grids buckling under the strain of increased usage, this is good for the environment and your utility bill.

The Economy of Quality

Sustainability-both environmental and financial-boils down to one philosophy. BIG DAISHOWA calls it The Economy of Quality, and it is the idea that true sustainability in manufacturing comes not from buying the cheapest tools and toolholders, but from buying ones that help you fully utilize every material and resource involved in your production.

Rather than focusing solely on the upfront price tag of the toolholder, look at the lifetime value. Premium tooling actually reduces total costs by ensuring cutting tools are used to their complete potential, parts are made right the first time, and equipment lasts its full expected lifespan.

So, what makes a toolholder sustainable?

Not all toolholders are created equal, but how will you know if a toolholder will deliver true sustainability and economy?

Sustainability starts with the toolholder's manufacturing, and controlling every aspect of production makes a crucial difference. If a toolholder brand does all manufacturing and quality control in-house, that is a step in the right direction.

From there:

- Ask about the AT tolerance, or the tolerance of the machine tool spindle as dictated by the machine manufacturer. Most machine spindles are ground to an AT1 tolerance; an AT2 tolerance on a toolholder is the ideal complement to this standard machine tool spindle tolerance. Many toolholder manufacturers grind to an AT3, which can compromise rigidity.

- Visually inspect and run your fingers over the toolholder. It should have a smooth, mirror-like finish. Even small burrs can compromise toolholder performance.

- Ask about quality control. Components should be thoroughly hand-inspected and measured.

- Look for toolholders that use high-quality tool steel (H13) in the toolholder itself, as well as in the collets, nuts, and retention knobs.

Choose the Right Tool for the Job

Even the highest-quality toolholder will not contribute to sustainability if it is not right for the application. If you are not sure about which tool assembly is right for a given job, ask your tooling partner. The possible combinations are nearly infinite, but here are a few examples:

- Heavy roughing often calls for milling chucks with maximum grip strength

- Long-reach applications usually require toolholders with additional vibration-damping tech

- Hydraulic chucks are sometimes a more repeatable alternative to shrink fit for applications that require extreme rigidity.

Find an expert partner who can help you troubleshoot and who will let you test their toolholders in the trenches.

Support and Expertise

Speaking of experts, good, knowledgeable support is priceless when it comes to toolholder success. An experienced application engineer has seen it all and will come with new ideas and insights you might not have even considered. In fact, they may identify sustainability and performance issues that contribute to inefficiencies and added costs.

In the end, shop sustainability goes a long way toward better business. And while there are many variables, getting the toolholding piece of the equation right goes a long way.

Authored by Jack Burley, President/COO, BIG DAISHOWA

For more information contact:

Jack Burley, President/COO

BIG DAISHOWA Inc.

2600 Huntington Blvd.

Hoffman Estates, IL 60192

888-TOOL-PRO / 224-770-2999

jack.burley@us.bigdaishowa.com

bigdaishowa@us.bigdaishowa.com

www.us.bigdaishowa.com