The new AF140 achieves cutter speeds up to 16,000 RPM and workpiece speeds up to 5,000 RPM, offering enhanced precision and efficiency.

With the AF140 replacing the AF90 and AF100, Affolter now offers a clear two-machine product line: AF140 and AF1600T.

Designed for gears up to 40 mm in diameter and module 1.0 mm, the AF140 is suited for high-precision industries.

Affolter Group has launched the AF140, company's newest gear hobbing center that is designed for small gears up to 40 mm in diameter and a maximum module of 1.0 mm. Positioned between and replacing the AF90 and AF100, the AF140 offers the strengths of its predecessors while introducing next-generation automation and connectivity features.

The AF140 was developed in close collaboration with users and industry partners to meet the growing demand for simplicity, compactness, versatility, and ingenuity in gear hobbing. Designed primarily for the watchmaking sector, the machine is equally suited for precision applications in micromechanics, aerospace, automotive, micromotors, robotics, and medical technologies.

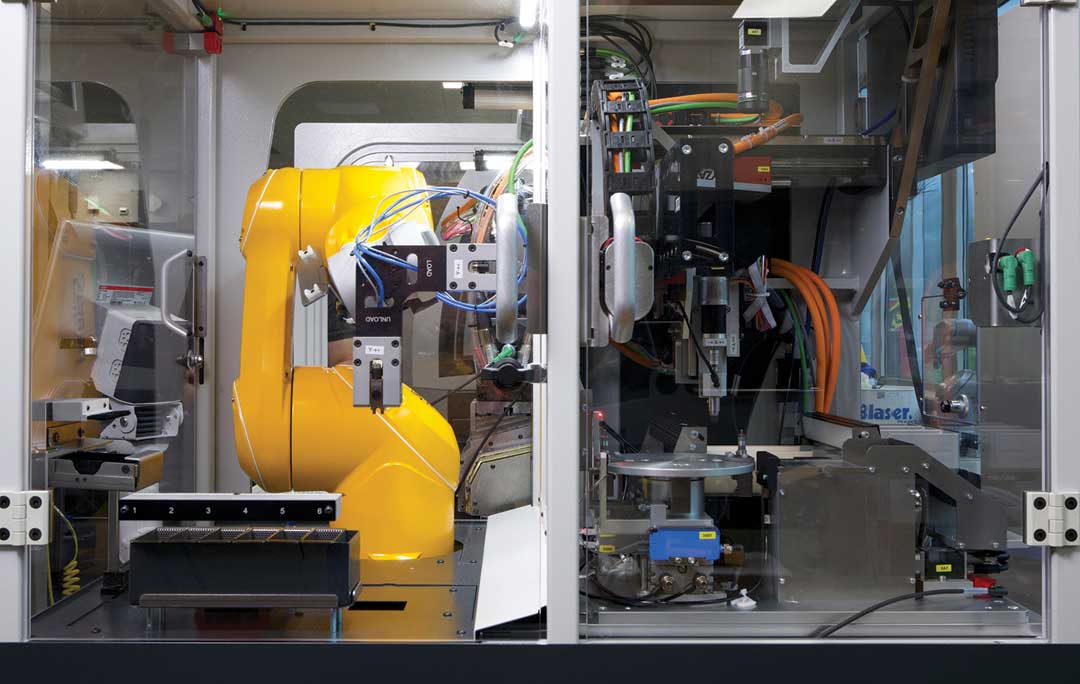

"With the AF140, we are offering our customers a perfect balance between performance, flexibility, and innovation," reported Mikael Affolter, Head of Sales at Affolter Group. "Its compact footprint makes it ideal for workshops where every square centimeter matters, while its compatibility with existing loaders and the option of a robotic arm provide new levels of automation and productivity. Combined with remote service features, the AF140 represents a true step forward in precision gear hobbing."

The AF140 reaches cutter rotation speeds of up to 16,000 RPM and workpiece rotation speeds of up to 5,000 RPM. The new and customizable robotic arm option for automatic loading and unloading significantly boosts the productivity of the AF140, enabling seamless automation and reliable 24/7 production. At the same time, the machine remains fully compatible with established loaders such as W20, W25, W31, AF45, deburring units, and more. Built on the Pegasus CNC platform, the AF140 provides digital integration with IO-Link sensors, simplified commissioning, and advanced remote service for real-time support and updates.

With the launch of the AF140, Affolter has streamlined its product line, replacing the AF90 and AF100 with a clear and future-ready two-machine portfolio: AF140 and AF160.

Mikael Affolter explained: "This simplification of our product portfolio further enhances our customer service capabilities, strengthens operational efficiency, and creates a solid foundation for growth and innovation in the coming years."

For more information contact:

Affolter Group

www.affoltergroup.ch/en

Rotec Tools Ltd.

100 Buckshollow Road, Ste. 3

Mohapac, NY 10541

845-621-9100

info@rotectools.com

www.rotectools.com