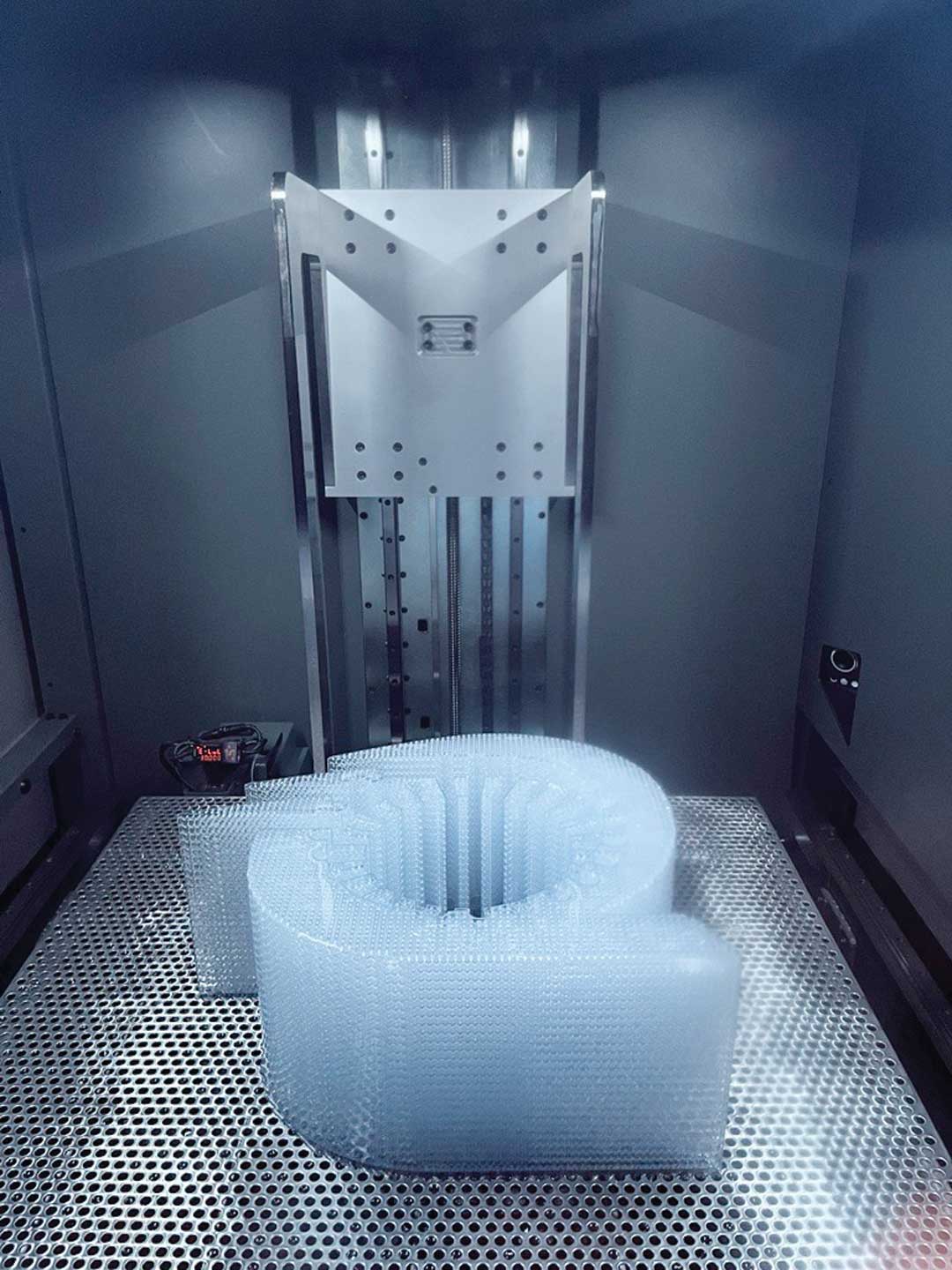

Quickparts SLA

Quickparts investment casting

Quickparts, a provider of on-demand manufacturing, has strengthened its commitment to "Limitless Manufacturing" with the completion of a $2.5 million expansion in new equipment and facility enhancements at its Seattle headquarters. The upgrades formally establish this site as an Aerospace & Defense Center of Excellence, strengthening the company's long-standing expertise in high fidelity casting patterns and advanced stereolithography (SLA). Simultaneously, Quickparts is officially launching its Quick Mold solution across North America, bringing production-quality molded parts to market in as little as five days.

"For more than three decades, we have been driving and redefining global manufacturing-delivering continuous innovation across on-demand services," said Avi Reichental, CEO of Quickparts. "As we continue to build our rich history and proven track-record of innovation to help companies rapidly address their most difficult manufacturing challenges, today's announcements are well aligned with this continued vision and commitment to customers."

With its latest investment, Quickparts has expanded QuickCast and next-generation SLA capacity in Seattle. This enables higher throughput, increased repeatability, and greater fidelity for precision investment casting patterns used in drone, satellite, propulsion, aviation, and defense systems. The expanded operation strengthens the company's ability to support aerospace and defense programs where consistency, dimensional accuracy, and repeatability are mission critical.

"This is not just an expansion-it is a strategic investment in the future of American manufacturing," said Aidan O'Sullivan, Americas President at Quickparts. "By expanding our QuickCast and SLA capabilities in Seattle, we are elevating support for aerospace and defense programs where precision is nonnegotiable, while also accelerating innovation for medical and automotive teams with speed-to-market tools like Quick Mold."

Quickparts is introducing Quick Mold to customers across North America following its strong adoption in Europe. Quick Mold offers production-quality injection-molded parts in as little as five days, enabling engineers to compress design cycles, validate materials early, and respond quickly to program changes, all with the support of Quickparts' engineering teams and expert DFM guidance.

Quick Mold leverages rapidly machined aluminum tooling and engineering-grade thermoplastics to move customers from design to functional, production-grade parts at high speed.

This process has already delivered measurable customer impact, including:

- One-day design change cycle using PA66 GF50

- Four-day turnaround for high-stress automotive components

- A luxury vehicle button redesigned, tooled, and molded in four days.

Quick Mold is now available to customers across North America.

For more information contact:

Quickparts

620 S Industrial Way

Seattle, WA 98108

206-203-1430

www.quickparts.com