Smith resharpening cutters for the carpet industry. It is the first grinder his father purchased and is still in use today.

Barron Smith at his desk.

Barron Smith and his dog Max, who goes to work every day with him.

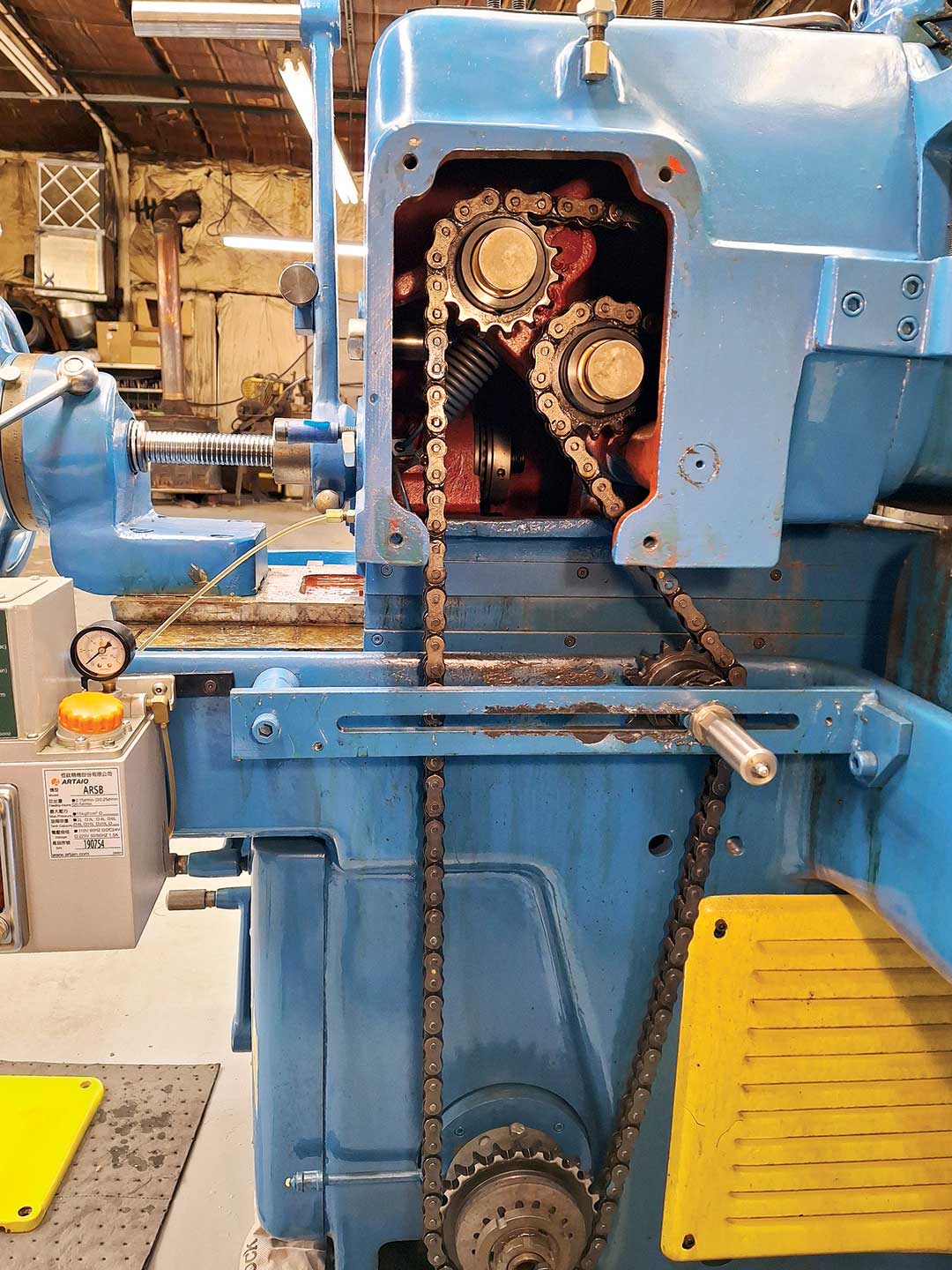

A #2 Cincinnati centerless grinder with a regulating wheel chain tensioner designed by Barron. This innovation is used on all of his centerless grinders.

A #2 Cincinnati centerless grinder with safety guard features a regulating wheel chain tensioner designed by Smith. This innovation is used on all of his centerless grinders.

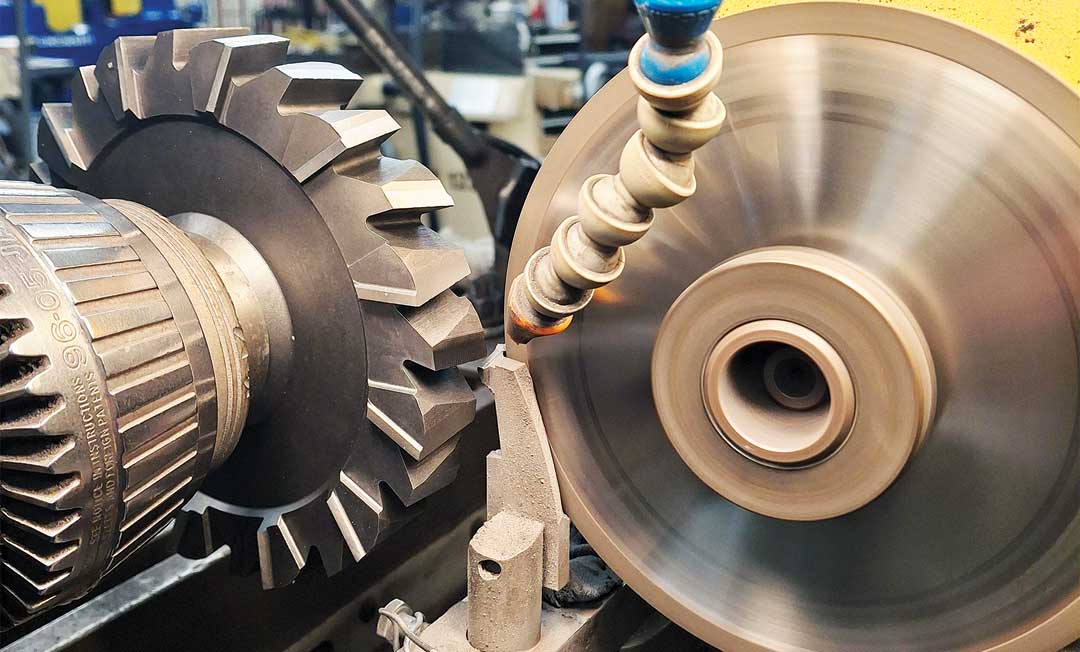

Centerless grinding a part.

Tool and cutter grinder.

One of Smith's remanufactured #2 Cincinnati centerless grinders.

A milling cutter being resharpened on a tool and cutter grinder.

What began in a DeSoto, TX, garage in 1972 has evolved into one of the region's few remaining manual grinding operations. Today, Barron Smith continues his father's legacy in North Oak Cliff, operating a fully equipped shop focused on close-tolerance centerless and tool and cutter grinding. With roughly 20 machines and decades of specialized expertise, Smith provides capabilities many modern CNC-focused shops no longer offer, maintaining a critical niche within the North Texas manufacturing landscape.

A Family Business Built on Grinding

Smith's father, Raphael Smith, launched R. W. Smith more than 50 years ago. A visionary in the cutting tool industry, the elder Smith remained dedicated to grinding throughout his career. In addition to tool and cutter grinding, he added centerless grinding capabilities during the 1980s.

After graduating with a business degree in 1989, Barron Smith joined the shop as a centerless grinder operator. With no internet and few resources available, he taught himself by working directly on the machines, honing his craft over the years with dedicated hands-on problem-solving and a commitment to mastering the details.

Following the passing of his father in 2016, Smith gradually transitioned to a solo-operator approach, consolidating work across the shop's manual and specialty machines. The change allowed him to maintain quality control while he continued to offer services that require hands-on expertise.

A One-Man Shop with Full Capabilities

The shop houses approximately 20 machines, including four centerless grinders and multiple tool and cutter grinders. Smith keeps each machine dedicated to a particular operation or wheel type, enabling rapid changeover and high efficiency. He also invests heavily in upgrades to maintain highest-quality standards in his close-tolerance precision work.

"People walk in and cannot believe it is just me here," Smith said. "But keeping the machines set up for specific work lets me move quickly. It is far faster than constantly swapping fixtures."

His workload spans a wide range of materials-titanium, high-nickel alloys, hardened tool steels, and other specialty grades. Much of the centerless work involves extremely close tolerances, frequently within ±0.0001", for parts such as pins, shoulder bolts, and long shafting as small as 0.090" diameter.

Smith also continues to support legacy applications that few modern shops maintain. He often modifies off-the-shelf inserts for specific applications using visual grinders-work that is typically performed on wire EDMs-along with other varied jobs such as resharpening milling cutters, grinding profiles on form/circular tools, and rebuilding 50 to 70-blade slicer assemblies to like-new condition.

Specialized Equipment and Custom Engineering

Smith relies heavily on his four solid cast iron Cincinnati centerless grinders, and recently invested in fully remanufacturing two of the machines with modern upgrades. These include variable-speed spindle drive, automatic wheel balancing systems, ball screws, and new hydraulics-bringing better-than-new performance to classic castings.

Smith noted that he can now control details such as wheel surface speed for optimal abrasive wheel performance, and he also takes advantage of an automatic grinding wheel balancing system that eliminates vibration-increasing time between wheel dressing cycles and improving surface finish.

Smith pointed out: "The machine castings are from the 40s through the 60s, and are still the first choice for a Centerless rebuild platform. While our quality has never suffered in the past, with the new upgrades I do not have to worry about downtime for repairs or upgrades moving forward. They are rock-solid and run as smoothly as anything new."

Smith also engineers custom fixturing and equipment for his own shop. One example is a proprietary tensioning system he designed and built in-house, now installed on three machines. The system improves stability, reduces vibration, and enhances performance on critical jobs.

"On a lot of work, the way you win it is by figuring out how to do it faster and more efficiently than the competition," he said. "Custom tooling and fixtures are a big part of that."

Serving Diverse Markets

Much of the shop's workload comes from oilfield, aerospace, medical, and contract machining customers. Many jobs are supplied by regional machine shops that perform the machining and heat treating before sending components to him for finish grinding.

Regardless of sector, accuracy remains the constant. Centerless grinding demands continual monitoring, frequent gauging, and precise process control.

"With the tolerances manufacturers expect today, there is not much gray area," Smith said. "It is either right or it is wrong. That is why people keep sending me work."

Preserving Skills-and Passing Them On

As manual grinding shops disappear, Smith acknowledges the scarcity of new talent entering the field. He volunteers on the advisory board for Dallas College Richland Campus' Precision Machining Technology program-one of the state's strongest programs of its kind, he noted.

The Machining Technology program at Dallas College gives aspiring machinists hands-on training in a modern, fully equipped lab where students work directly on CNC machining centers and precision metalworking equipment. Through a variety of credentials-from short-term workforce certificates to a two-year degree-the program equips students with the skills necessary to produce metal parts from solid stock to tight tolerances, preparing them for roles in aerospace, medical, defense, and high-tech manufacturing.

Smith also supports Dallas College's Uniquely Abled Academy (UAA) program. The UAA at Dallas College-hosted on the Eastfield Campus-is a 15-week, fast-track machining training program designed specifically for adults with Level-1 (high-functioning) autism. Through hands-on instruction in machining and CNC operations, students learn essential skills such as set-up and operation of CNC mills and lathes, blueprint reading, measurement and quality control practices, and shop mathematics. Students receive support from dedicated UAA staff for enrollment and career guidance, and the program helps connect graduates with employers who value the unique strengths that neurodiverse individuals often bring, such as consistency and attention to detail. In many cases, tuition and training costs are covered through grant support, making the program accessible to qualified applicants.

"These students are incredibly focused," Smith said. "It has been impressive to see how well they adapt to a production environment."

A Niche Worth Keeping

While he describes his business as "just a small shop," Smith fills a vital role in the local manufacturing ecosystem. His combination of manual expertise, legacy capabilities, and advanced remanufactured equipment gives customers access to services that are increasingly rare.

"There are not many people doing what I do anymore," he said. "But there is still a real need for it. And as long as that is the case, I will keep doing it."

---------------------------------------------------

Capabilities at a Glance: R. W. Smith Company, Inc.

Centerless Grinding

Diameters: .080" to 3.0"

Tolerances: ±0.0001"

Equipment: Four remanufactured Cincinnati centerless grinders

Work types: through-feed, in-feed and close-tolerance precision work

Tool & Cutter Grinding

Custom regrinds for carbide inserts and HSS tools

Form grinding and specialty profiles

Custom broaches, gear cutters, circular cutters, undercut, and reduced-shank tools

Legacy, one-off, and nonstandard geometries

Supplemental Machining

Manual milling and turning for fixture work and secondary ops

Surface grinding for flats, steps, and small components

Job Characteristics

Short-run and specialty parts

Tight-tolerance custom work

Projects unsuited to volume-driven CNC environments

---------------------------------------------------

For more information contact:

Barron Smith, Owner

R. W. Smith Company, Inc.

1318 West Commerce Street

Dallas, TX 75208-1401

214-748-1699

barron@rwscompany.com

www.rwscompany.com

Dallas College

Richland Campus

12800 Abrams Road

Dallas, TX 75243

972-669-6400

askMIT@dallascollege.edu

dallascollege.edu/study/

machining-technology

Dallas College

Eastfield Campus

3737 Motley Drive

Mesquite, TX 75150

972-860-7100

www.dallascollege.edu/uaa