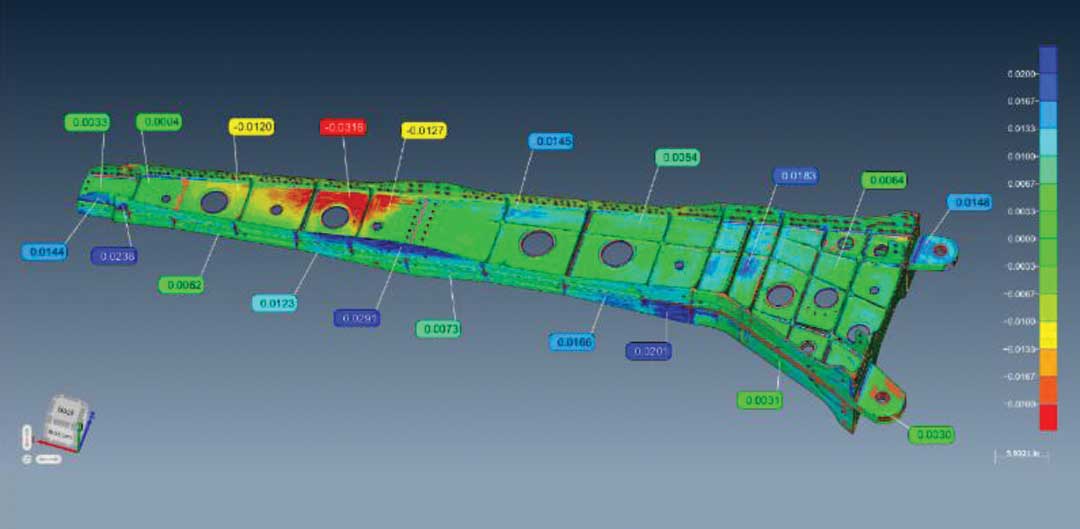

New Thickness Analysis is just one of many new features included in Verisurf 2026. It inspects part thickness using 3D scan data for fast, accurate reporting of wall, rib, and floor thickness deviation across the entire part.

Verisurf Software, Inc. has released Verisurf 2026, the latest version of its model-based metrology platform. Verisurf 2026 introduces new features and workflow improvements designed to help manufacturers reduce costs, save time, and enhance repeatable process control across all stages of digital manufacturing.

"For manufacturers, measurement and inspection are no longer just end-of-line tasks, but vital parts of a fully connected production process," said a company spokesperson. "Verisurf 2026 strengthens this integration by offering faster, more accurate, and more reliable methods to handle inspection data, verify parts and assemblies, and connect design intent with the final product."

"Verisurf 2026 is built on direct feedback from our customers who need more than measurement tools; they need a way to connect quality data with every stage of the manufacturing process," said Ernie Husted, President and CEO of Verisurf Software. "By embedding metrology into the digital workflow, manufacturers gain not only faster inspection, but also greater visibility, repeatability, and control of their entire production process."

Enhancements That Drive Productivity and Process Control

"Verisurf 2026 delivers meaningful updates to key modules, including CAD with Model-Based Definition (MBD), Measure, Build, Analysis, Automate, and Reverse," said the spokesperson. "It also expands device compatibility and strengthens interoperability. Together, these improvements empower users to take on more complex inspection, reporting, and reverse engineering tasks with ease and confidence."

Highlights include:

- Levels & Plane Manager: A redesigned interface gives users better visibility and control of data layers and WCS frames, improving workflow organization and reducing time spent managing large CAD files.

- Thickness Analysis: A new tool for part-thickness inspection using 3D scan data, offering fast, accurate, visual reporting of wall, rib, and floor thickness deviation across the entire part.

- Measure: New auto-alignment algorithms, orientation constraints, and expanded cloud post-processing provide faster, more reliable results for live-capture scanning.

- QIF Integration: Read/write support for the Quality Information Framework (QIF) enables seamless interoperability with enterprise data systems and enhances standardized digital thread communication.

- Verisurf Device Interface (VDI): Expanded compatibility now includes support for the Leica ATS800 by Hexagon, Renishaw Equator X, and MTConnect for Haas 3- and 5-axis on-machine probing, giving manufacturers greater flexibility to deploy inspection across the shop floor.

Building the Connected Quality Ecosystem

With its open-platform architecture, Verisurf 2026 supports interoperability across a wide range of coordinate measuring machines (CMMs), scanners, and software. This flexibility is key for manufacturers seeking to unify their measurement, inspection, and reporting processes under a single digital framework.

The software enables real-time feedback and a fully traceable data stream, closing the loop between design, planning, production, and quality control. By embedding inspection data directly into the digital workflow, manufacturers can ensure that every part meets specifications, scrap and rework are reduced, and time-to-market is accelerated.

This capability is particularly valuable for industries such as aerospace, automotive, energy, and medical devices, where regulatory compliance, supply chain collaboration, and process validation are critical. By supporting QIF standards and expanding device compatibility, Verisurf 2026 helps organizations maintain consistent quality while integrating intelligent data with existing enterprise resource planning (ERP), statistical process control (SPC), and product lifecycle management (PLM) systems.

"Manufacturers do not just need more data; they need actionable insights delivered in real time," Husted said. "With Verisurf 2026, we have expanded capabilities while keeping workflows intuitive and repeatable for process control-a key tenet of quality."

Whether used for inspection, reverse engineering, or tool building, the automated process control inherent in Verisurf supports Industry 4.0 initiatives and continuous improvement across industries. Verisurf solution suites are purpose-based, and additional application modules can be added as needs grow. Verisurf offers flexible licensing options, including subscription, perpetual, standalone, and network licenses, as well as license borrowing to meet individual customer needs.

Verisurf Solution Suites

- Metrology Enterprise Suite (includes all application modules)

- CMM Programming and Inspection Suite

- Inspection & Analysis Suite

- 3D Scanning & Reverse Engineering Suite

- Tool Building and Inspection Suite

- Scan Data Suite

- Inspection Planner Suite.

For more information contact:

Verisurf Software, Inc.

4907 E Landon Dr.

Anaheim, CA 92807

888-713-7201 / 714-970-1683

sales@verisurf.com

www.verisurf.com