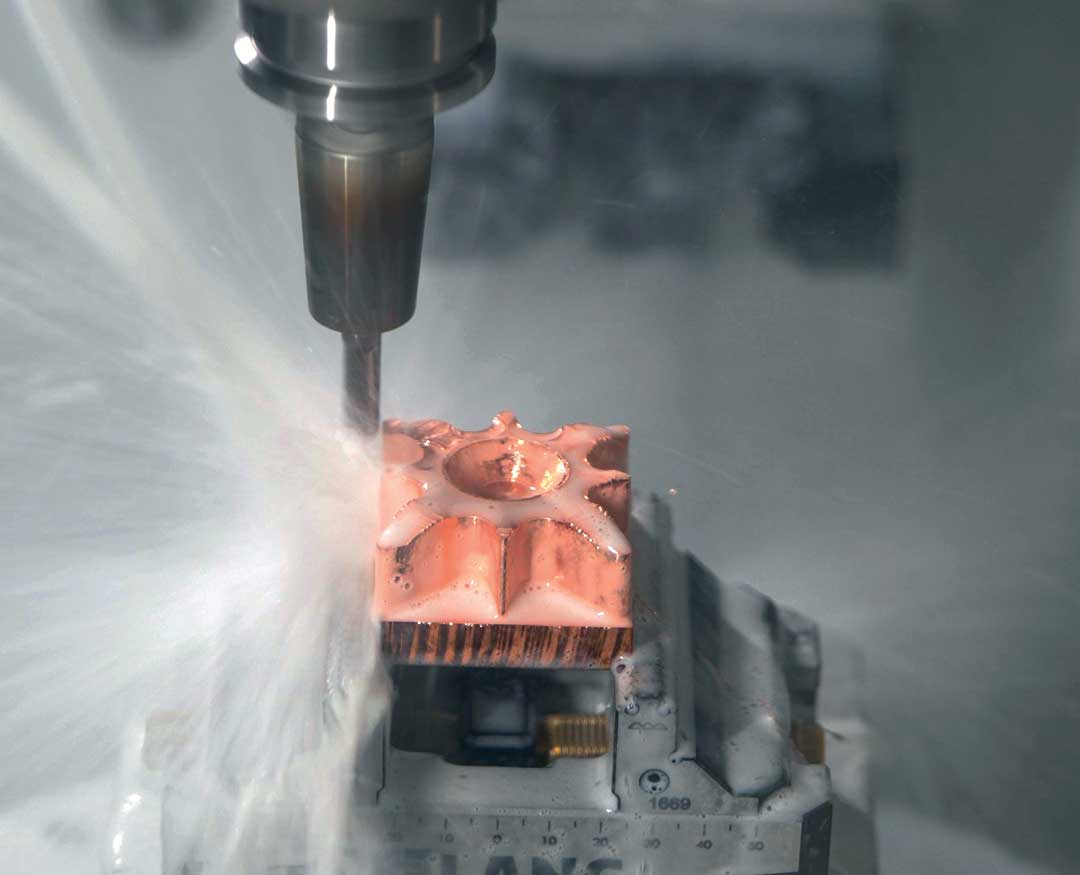

Get to the copper electrode faster with the tool C-Razor by Hufschmied.

Due to its geometry, coating, post-treated cutting edges, and polished chip groove, the C-Razor mills copper faster and with better results than conventional tools, Hufschmied reported.

Hufschmied Zerspanungssysteme set itself the task of improving the manufacture of copper electrodes for spark erosion machining. The result is the C-Razor milling tool series. The HSC tools, which have been specially developed for copper machining, reduce machining times, have a long service life, and produce products with enhanced surface quality and maximum dimensional accuracy, the company reported. This is achieved by sharp, polished, and coated tools with optimized tool geometry and specially post-treated cutting edges.

"Copper has some unfavorable properties in machining, which Hufschmied addresses with the C-Razor," said a company spokesperson. "The high ductility and tendency to stick lead to built-up edges. This phenomenon is exacerbated by the material's good thermal conductivity. The low heat concentration at the cutting edge can lead to work hardening. The result of particularly persistent material build-up on the cutting edge is poor surface quality and increased tool wear. Good chip removal is therefore particularly important for copper machining tools. Hufschmied achieves this with polished chip groove, among other things."

The soft structure of copper can also lead to unwanted vibrations during milling, which has a negative effect on dimensional accuracy. Stable machine guidance is therefore essential. "When optimizing milling operations, in addition to suitable tools and cleverly selected tool paths, the cutting parameters always play a major role," explained Christel Hufschmied, Managing Director of Hufschmied Zerspanungssysteme GmbH. "Given the properties of the material described above, this is particularly true for copper. That is why we also provide recommendations for cutting speed, feedrate, and cutting depth with the C-Razor."

The C-Razor tool family for copper electrode production includes torus milling cutters and ball milling cutters with diameters from 0.3 to 12 mm.

For more information contact:

Hufschmied Zerspanungssysteme

info@hufschmied.net

www.hufschmied.net