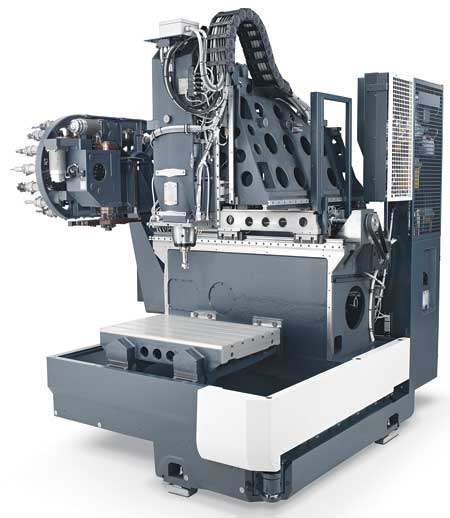

DMC 650 V

The DMC 650 V is designed to provide enhanced power and flexibility.

According to the company, cooling of the ball screw drives and guides improves accuracy and long-term operation.

DMG MORI offers its third generation vertical machining center (VMC), the DMC 650 V. According to the company, this series features a new machine concept and improved technical data.

The machine bed is made of mineral casting, on which the rigid table with a clamping surface of 900 x 570 mm rests. The cast iron machine column forms the basis of the X/Y slide. Only the tool moves. In combination with the fixed table, this enables workpiece weights of up to 800 kg. The rapid traverses in all axes are 36 m/min. Instead of a 10,000 RPM spindle, the standard version spindle is now 14,000 RPM and 121 Nm (spindle versions up to 24,000 RPM are available as options). The traverse paths have also been improved to 650 x 520 x 475 mm.

New in this machine is the cooling of the drives and guides. The ball screw nuts and linear guides are cooled via contact pressure rails to dissipate frictional heat.

The machine features an SK 50 spindle with 10,000 RPM and 303 Nm for heavy machining. The tool magazine features 20 pockets and can optionally be extended to 30, 60 or 120 pockets. "Enhanced performance data provide the user with a number of possible applications," said a company spokesperson. "These include sophisticated single item production, heavy machining with high metal removing volumes and serial production combined with automation solutions."

The DMC 650 V is initially available with a 19" ERGOline with Siemens 840D solutionline and Operate 4.5, as well as with the Heidenhain TNC640. This will be followed in the second quarter of 2014 by CELOS with 21.5" ERGOline and Siemens.

For more information contact:

DMG MORI USA

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

www.dmgmori.com